Ginsan

-

-

The Harmony of Tradition and Modern Stainless Excellence

Ginsan steel captures the soul of carbon steel with the convenience of stainless — delivering a rare harmony of sharpness, easy sharpening, and rust resistance that chefs around the world rely on every day.

-

Ginsan Japanese Knife Collection

-

Ginsan Deba 180mm -Mirror Polished(both sides)

Regular price $403.00 CADRegular priceUnit price / per$0.00 CADSale price $403.00 CADSold out -

Sold out

Sold outGinsan Gyuto 240mm -Kido Finishing

Regular price $410.00 CADRegular priceUnit price / per$0.00 CADSale price $410.00 CADSold out -

Ginsan Usuba 210mm -Mirror Polished(one side)

Regular price $412.00 CADRegular priceUnit price / per$0.00 CADSale price $412.00 CADSold out -

Ginsan Yanagiba(Kiritsuke) 225mm -Mirror Polished(both sides)

Regular price $412.00 CADRegular priceUnit price / per$0.00 CADSale price $412.00 CADSold out -

Ginsan Gyuto 210mm -Mirror Polished(both sides)

Regular price $430.00 CADRegular priceUnit price / per$0.00 CADSale price $430.00 CADSold out -

Ginsan Deba 210mm -Mirror Polished(one side)

Regular price $430.00 CADRegular priceUnit price / per$0.00 CADSale price $430.00 CADSold out -

Ginsan Gyuto (Kiritsuke) 240mm -Kido Finishing

Regular price $460.00 CADRegular priceUnit price / per$0.00 CADSale price $460.00 CAD -

Ginsan Yanagiba(Kiritsuke) 270mm -Mirror Polished(both sides)

Regular price $480.00 CADRegular priceUnit price / per$0.00 CADSale price $480.00 CAD -

Ginsan Gyuto 240mm -Mirror Polished(both sides)

Regular price $490.00 CADRegular priceUnit price / per$0.00 CADSale price $490.00 CADSold out -

Ginsan (Honyaki) Gyuto 210mm -Mirror Polished(both sides)

Regular price $615.00 CADRegular priceUnit price / per$0.00 CADSale price $615.00 CADSold out -

Ginsan (Honyaki) Gyuto 240mm -Mirror Polished(both sides)

Regular price $655.00 CADRegular priceUnit price / per$655.00 CADSale price $655.00 CADSold out -

Ginsan (Honyaki) Gyuto 270mm -Mirror Polished(both sides)

Regular price $685.00 CADRegular priceUnit price / per$685.00 CADSale price $685.00 CADSold out -

Ginsan (Honyaki) Yanagiba 270mm -Mirror Polished(both sides)

Regular price $710.00 CADRegular priceUnit price / per -

Ginsan Damascus Yanagiba(Kiritsuke) 270mm -Mirror Polished(both sides)

Regular price $740.00 CADRegular priceUnit price / per$0.00 CADSale price $740.00 CADSold out -

Ginsan Damascus Santoku(Kiritsuke) 180mm-Mirror Polished(both sides)

Regular price $750.00 CADRegular priceUnit price / per$0.00 CADSale price $750.00 CADSold out -

Ginsan Damascus Yanagiba(Sakimaru) 300mm -Mirror Polished(both sides)

Regular price $810.00 CADRegular priceUnit price / per$0.00 CADSale price $810.00 CAD

KIREAJI's Three Promises to You

-

1. Forged in the Legacy of Sakai

From Sakai City—Japan’s renowned birthplace of professional kitchen knives—each blade is crafted by master artisans with over six centuries of tradition. Perfectly balanced, enduringly sharp, and exquisitely finished, every cut carries the soul of true craftsmanship.

-

2. Thoughtful Care for Everyday Use

Every knife includes a hand-fitted magnolia saya for safe storage. Upon request, we offer a complimentary Honbazuke final hand sharpening—giving you a precise, ready-to-use edge from day one.

-

3. A Partnership for a Lifetime

A KIREAJI knife is more than a tool—it is a lifelong companion. With our bespoke paid aftercare services, we preserve its edge and beauty, ensuring it remains as precise and dependable as the day it first met your hand.

Why Many Product Photos Show Only the Blade

At KIREAJI, every knife is made to order in Sakai, Japan. Photos show the blade before the handle is attached, allowing artisans to perfect the balance and edge for your specific order. Your knife arrives fully finished — tailored just for you.

Global Delivery from Sakai

Across the world, discerning cooks seek authentic Japanese knives from Sakai — Japan’s legendary knife-making city with over 600 years of tradition.

At KIREAJI, we work alongside master artisans in Sakai to fulfill that desire, shipping genuine handcrafted knives directly from the workshop to kitchens worldwide.

Ginsan

-

The Ultimate Stainless Steel Honoring Tradition and Empowering Today’s Chefs

The saying, “The soul of a knife lies in its steel,” perfectly captures the essence of Ginsan.

Beloved in the world of traditional Japanese knives for decades, Ginsan embodies the very spirit of Japanese craftsmanship by seamlessly combining the sharpness of traditional steel with the corrosion resistance demanded by modern kitchens. -

A Perfect Balance of Carbon Steel Sharpness and Stainless Steel Durability

The greatest appeal of Ginsan lies in its ability to offer the sharpness and ease of sharpening comparable to carbon steel, while firmly maintaining the rust resistance characteristic of stainless steel.

This exquisite balance is a true work of art born from the meticulous adjustments and skill of master artisans. -

Crafted by Skilled Artisans, Delivering Unmatched Sharpness and Texture

Ginsan stands apart from mass-produced steels.

Each blade is carefully forged by experienced craftsmen, painstakingly hammered and stretched to achieve a perfect harmony between toughness and flexibility.

This results in a knife that becomes more comfortable with use, delivering a satisfying rebound and precise control with every cut. -

A Worthy Investment Marked by Time and Craftsmanship

Due to the intensive labor and skill poured into each blade, Ginsan knives are not inexpensive.

However, their price reflects not just the numbers but the advanced forging techniques, the premium materials used, and the invaluable enhancement they bring to a cook’s culinary journey. -

The Perfect Choice For Those Who:

- Wish to incorporate the authentic sharpness and feel of traditional Japanese knives into their daily cooking

- Desire a rust-resistant and easy-to-maintain blade

- Seek a genuine, artisan-crafted knife that represents true quality and passion

Ginsan is the ideal companion for today’s busy chefs who still appreciate and uphold the soul of Japanese blades. -

Ginsan — Honing the Chef’s Skill and Sensibility, Passing Tradition to the Future

As you use it, Ginsan grows richer in character and fits your hand ever more naturally. It is not merely a kitchen tool but a masterpiece imbued with the pride of craftsmanship and a partner that fully amplifies the chef’s expressive potential.

The sharpness felt with each cut represents the ultimate partnership in the art of cooking.

Ginsan is the blade that opens new possibilities and brings joy to your culinary creations—truly a knife that shapes the future.

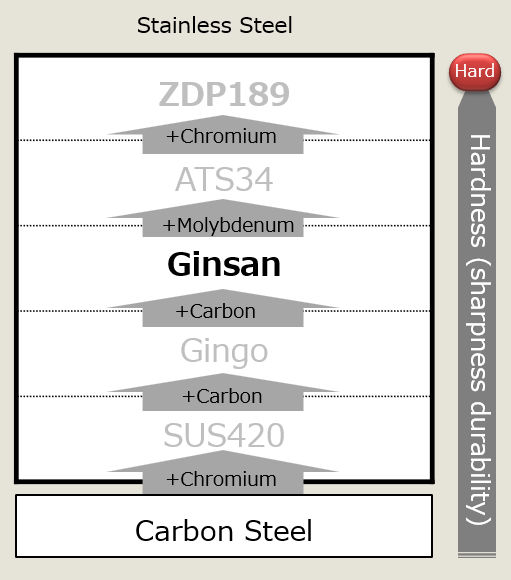

Ginsan’s balance between corrosion resistance and cutting performance makes it an excellent choice for knife materials. With a high chromium content of 13-16%, it offers strong resistance to corrosion, while its carbon content ranges from 0.8 to 1.3%, striking a balance between hardness and toughness to ensure stability during use.

Because of its superior sharpness and resistance to rust, Ginsan is extensively used in kitchen knives, trusted by both professional chefs and home cooks alike. It enhances daily culinary tasks, making them more efficient and enjoyable.

Features of Ginsan

-

Comparable Sharpness to Carbon Steel

Ginsan is a material with high carbon content and exceptional hardness. When sharpened, it exhibits sharpness comparable to steel knives.

-

Most Sharpenable Among Stainless Knives

With a hardness of around HRC 60, similar to carbon-based Japanese knives, Ginsan mitigates the typical difficulty of sharpening associated with stainless steel, making it relatively easy to handle even for beginners.

-

Rust-Resistant with Minimal Food Adhesion

Ginsan knives are highly resistant to rust and offer minimal food adhesion while cutting. This makes them a favorite among Japanese culinary craftsmen.

Recommended Users for Ginsan

-

1.Tradition-Loving Modern Chefs

Chefs who want the authentic sharpness and feel of traditional Japanese knives, but with the rust resistance needed in a busy modern kitchen. Ginsan offers the soul of carbon steel without the same maintenance demands.

-

2. Professionals Seeking Easy Sharpening in Stainless Steel

Among stainless steels, Ginsan is one of the most sharpenable. Its hardness (~HRC 60) allows precise edge work, making it ideal for chefs who value both performance and convenience.

-

3. Culinary Enthusiasts Investing in Artisan Craftsmanship

For those who value the skill of the blacksmith as much as the steel itself, Ginsan knives are handmade by experienced craftsmen. Each blade offers a refined cutting experience that improves over time.

Why Ginsan Is So Difficult to Forge

-

Ginsan is celebrated for its rare balance: the sharpness and sharpening feel of carbon steel, combined with the rust resistance of stainless. But what truly defines its value is not just the steel itself—it is the difficulty of bringing out its full potential.

-

-

Unlike ordinary stainless steels, Ginsan has a carbon composition close to high-carbon steels. This gives it extraordinary sharpness and hardness, but also makes it one of the most demanding steels to forge. Precise temperature control is essential: a moment too hot or too cool, and the blade’s performance is lost. Its toughness makes shaping labor-intensive, and only a handful of smiths in Japan possess the mastery to work it properly.

-

Many of KIREAJI’s Ginsan knives are forged by Shougo Yamatsuka, a master craftsman renowned for his skill and precision. His Ginsan blades are admired for their balance, resilience, and delicate yet enduring edge—a true marriage of rust resistance, tradition, and expressive cutting performance.

-

For chefs, owning a Ginsan knife is more than acquiring a tool. It is holding a living tradition—600 years of Sakai craftsmanship carried forward with relentless innovation. Each cut reflects not only the steel’s qualities but the spirit of the craftsman who forged it, transforming everyday cooking into an art.

FAQ About Ginsan

Q1. What is Ginsan?

Ginsan, also known as Gingami No.3, is a premium stainless steel originally developed by Hitachi Metals (now Proterial, Ltd.). By raising the carbon content within a stainless steel framework, it achieves a balance of hardness and edge retention while preserving the corrosion resistance expected from stainless alloys. This makes Ginsan an ideal steel for high-performance kitchen knives that combine tradition with practicality.

Q2. What are the key features of Ginsan?

Ginsan offers a rare combination of qualities. It delivers sharpness comparable to carbon steel, yet resists rust like stainless. It is also one of the easiest stainless steels to sharpen, providing smooth feedback on the whetstone. In addition, food is less likely to stick to its clean, fine-grained surface, making it an excellent choice for both professional kitchens and daily use.

Q3. How are Ginsan knives made?

Unlike mass-produced stainless knives that are stamped from sheets of steel, Ginsan knives are often hand-forged by skilled artisans. This forging process allows careful shaping, precise heat treatment, and meticulous finishing. The result is a blade that not only performs at a higher level but also carries the individuality and artistry of its maker.

Q4. Who are Ginsan knives best suited for?

Ginsan knives are favored by professional chefs, especially in Japanese cuisine, because they balance sharpness, durability, and ease of maintenance. At the same time, they are excellent for home cooks who want the performance of a high-end knife without the demanding care that carbon steels require.

Q5. Is Ginsan truly stainless?

Yes. Ginsan is classified as a stainless steel, containing around 13–14.5% chromium, which gives it strong corrosion resistance and clearly distinguishes it from traditional carbon steels. In practical use, this means rust is rarely an issue if the knife is washed and dried promptly after cooking. However, because of its high carbon content, some chromium bonds into carbides during heat treatment, which slightly reduces the free chromium available for corrosion protection. As a result, while Ginsan is highly resistant to rust, it is not completely maintenance-free. With simple care—washing, drying, and storing properly—it will remain bright and stainless for many years.

Q6. How should I maintain a Ginsan knife?

Maintenance is simple. Wash and dry the knife immediately after use, avoid leaving it in damp conditions, and use appropriate cutting boards. Regular sharpening with waterstones will keep the edge in peak condition. For long-term storage, store in a dry place with a blade guard. With thoughtful care, a Ginsan knife will last for decades while retaining its beauty and sharpness.

Japanese Knife Materials

The steel behind a Japanese knife defines its sharpness, durability, and care. From traditional carbon steels like White #2 and Blue #2 to modern innovations such as Ginsan and ZDP189, each material offers its own balance of performance and maintenance. This guide explores how these choices shape the knives we use today.

Ginsan – The Fusion of Tradition and Modern Technology

Ginsan is a premium stainless steel that combines razor-sharp edges with rust resistance. Unlike typical stainless steels, it behaves more like carbon steel—easy to sharpen, yet long-lasting. Its unique composition allows forging to enhance strength and durability, making it a top choice for both professional chefs and home cooks seeking high performance with low maintenance.

The Soul of Craftsmanship

-

Ginsan Steel — The Perfect Balance of Sharpness, Ease, and Tradition

Among the many steels available, Ginsan has long been the quiet favorite of true craftsmen. Its edge is sharp from the very first cut, and with just a few passes on the whetstone, it returns to life again and again. This balance of performance and care makes it a trusted companion in the hands of professionals.

-

But what truly sets Ginsan apart is how it complements the delicate art of Japanese cooking. The balance between the blade’s durability and its ability to slice through ingredients with precision makes it ideal for preparing dishes that demand attention to detail. Whether it’s the perfect cut of fish for sushi or the delicate preparation of vegetables for kaiseki, Ginsan excels in enhancing the experience.

-

For us artisans, Ginsan is more than stainless steel. It is proof that durability and refinement can coexist, and that a knife can embody both modern practicality and centuries of tradition. When you hold a Ginsan knife, you hold not just a tool—but a partner that reflects the heart of Japanese craftsmanship.

How Japanese Knives Are Made: The Sakai Tradition

VIDEO PROVIDED: JAPAN TRADITIONAL CRAFTS AOYAMA SQUARE (YOUTUBE)

-

Sakai Forged Blades — Six Centuries of Unrivaled Craftsmanship

Loved by chefs around the world and trusted by 98% of Japan’s top culinary professionals, Sakai knives are more than tools—they are the living legacy of over 600 years of master craftsmanship.

-

At KIREAJI, we work directly with the Shiroyama Knife Workshop in Sakai, Japan, ensuring every blade is hand-forged, finished to perfection, and shipped straight from the workshop to kitchens across the globe. No middlemen. No mass production. Only authentic, artisan-made knives, crafted to elevate your cooking for a lifetime.