Traditional Craftsmen Collection

-

-

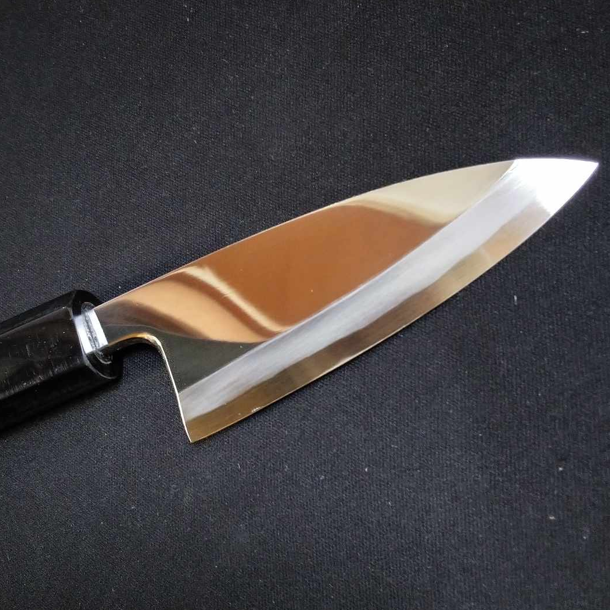

The Japanese knives crafted by the artisans of Sakai City boast over 600 years of history and tradition. We promise to deliver this exceptional quality to our customers.

The Pinnacle of a Craft: Sakai’s Traditional Bladesmiths

-

Sakai’s Traditional Craftsmen represent the highest tier of Japanese bladesmithing.

With over 12 years of training, rigorous national exams, and a lifelong commitment to mastery, only 28 certified masters remain today.

They are the guardians of Japan’s ancient knife tradition—preserving techniques, elevating quality, and forging blades with spirit, precision, and devotion. -

The Art of the Blacksmith

-

A blacksmith is more than a metalworker — they are an artisan who breathes life into raw steel through skill, precision, and centuries-old tradition.

While machines can produce knives in quantity, only the hands of a master can forge a blade with true character and soul — a difference you can feel in every cut. -

Shogo Yamatsuka

A master blacksmith famed for his skill in forging rare Ginsan steel. Certified as a Traditional Craftsman in 2012, he personally handles every step from forging to sharpening, earning the trust of professional chefs worldwide.

Satoshi Nakagawa

The youngest Traditional Craftsman in Sakai’s history, trained 16 years under master Kenichi Shiraki. Known for precision and artistry, he now leads Nakagawa Hamono, creating blades that blend tradition and innovation.

Keijiro Doi

Master of yanagiba and mukimono usuba knives, certified as a Traditional Craftsman in 1987. Awarded the Blue Kiriba Award in 1997, he retired in 2012 and passed away in 2017, leaving rare and highly valued works.

Tadashi Enami

A fifth-generation blacksmith preserving ancient fire-forging while embracing innovation. Certified in 2003 and honored as a Sakai City Meister in 2007, he is renowned for meticulous craftsmanship and made-to-order knives.

Yuzan

A legendary craftsman who mastered Mizuyaki Honyaki, among the most difficult forging techniques. His rare works are almost impossible to find, and his legacy lives on through his son, Shogo Yamatsuka.

Kenichi Shiraki

Renowned for his mastery of Honyaki and water-quenching techniques, producing knives of unmatched sharpness. Now retired, his rare works are treasured, with his legacy carried on by apprentice Satoshi Nakagawa.

Tatsuo Ikeda

Third-generation head of Ikeda Cutlery, famed for Honyaki forging and the Fuji wave pattern. Honored with the Order of the Sacred Treasure in 2009, his works remain rare treasures since his passing in 2015.

Yoshikazu Ikeda

President of the Sakai Uchihamono Traditional Craftsmen Association and co-founder of Ikeda Tanrenjo. Certified in 1988 and awarded Osaka’s Outstanding Artisan Award in 2014, he is known for his relentless pursuit of perfection.

The Craft of the Blade Sharpener

-

The sharpener is the final guardian of the blade, reading its unique character and refining its edge with meticulous care.

Each stroke of the whetstone reveals the knife’s full potential, creating unmatched sharpness and balance — trusted by the world’s finest chefs. -

Tadayoshi Yamatsuka

Certified as a Traditional Craftsman in 2022, he is renowned for exceptional mirror-polishing skills. His beautifully finished blades captivate chefs in Japan and around the world.

Shotaro Nomura

Certified as a Traditional Craftsman in 1988, he has over 60 years of sharpening experience. Trained under the legendary Mr. Ino, he is known for knives that grow more beautiful and perform better with each use.

How Traditional Japanese Knife-Making Skills Are Passed Down

-

A Legacy Forged in Apprenticeship

In Sakai, the heart of Japanese knife-making for centuries, skills are not learned from books but from masters—through years of close observation, repetition, and guidance. Young artisans enter long-term apprenticeships, where discipline and patience shape both their hands and their spirit.

-

Learning by Watching and Listening

The craft is passed down through kuden (oral instruction) and mite nusume—“stealing with the eyes.” Every subtle motion—angle, pressure, rhythm—is absorbed by watching the master at work, then practiced until it becomes second nature. These delicate nuances cannot be captured in manuals, only in person.

-

A Community that Sustains the Craft

The survival of Sakai’s knife-making is supported not only by tradition but also by the community. Training programs, subsidies, and the prestigious Dento Kogeishi (Traditional Craftsman) certification help young artisans set goals and earn recognition.

-

Preserving Techniques That Time Cannot Replace

From hand-forging with pine charcoal to water quenching and natural whetstone sharpening, many processes remain unchanged. These methods endure not out of nostalgia, but because they create knives of unmatched quality—blades that carry the soul of their maker.

-

Tradition for the Next Generation

This heritage thrives because it is more than skill transfer—it is a human connection built on trust, pride, and shared purpose. In Sakai, the union of master and apprentice, supported by an entire community, ensures that these knives will continue to embody authenticity and excellence for generations to come.

Passing the Flame: How Sakai’s Knife Heritage Lives Through Human Connection

-

Sakai’s knife-making tradition endures not through manuals but through direct human transmission, where apprentices learn by observing, imitating, and absorbing the master’s subtle techniques.

This deep, community-supported mentorship preserves skills that cannot be replaced, ensuring the unmatched quality of Sakai blades for generations to come. -

Why Do 98% of Japan’s Chefs Trust Sakai Knives?

For over 600 years, Sakai has perfected a unique craft where each stage—forge, sharpen, finish—is mastered by specialists. This tradition makes Sakai the birthplace of Japan’s most trusted knives.

The 98% Statistic: More Than a Number

According to the Sakai Tourism Bureau, “98% of Japanese chefs use Sakai knives.” This figure isn’t just a claim—it reflects the deep trust chefs place in Sakai’s centuries-old craftsmanship.

The Master Craftsmen of Sakai Uchihamono

In Sakai, centuries-old techniques are carried forward by government-certified Traditional Craftsmen. Each knife is not just a tool but a living symbol of tradition, precision, and spirit—kept alive through their hands.

Preserving Sakai Blades: Challenges, Succession, and the Future

Sakai’s forged blades face shrinking demand, aging artisans, and global price competition. This article examines how the city is confronting these challenges through training programs, skill digitization, and modern outreach—revealing what it takes to keep a thousand-year craft alive.

Sakai’s Dwindling Masters: A Legacy at Risk

Once the heart of Japan’s finest cutlery, Sakai now has only a handful of blacksmiths left. With rising competition and fading interest among the young, new markets and fresh apprentices are vital to survival. Supporting these craftsmen means safeguarding a 600-year cultural legacy.

How Japanese Knives Are Made: The Sakai Tradition

VIDEO PROVIDED: JAPAN TRADITIONAL CRAFTS AOYAMA SQUARE (YOUTUBE)

-

Sakai Forged Blades — Six Centuries of Unrivaled Craftsmanship

Loved by chefs around the world and trusted by 98% of Japan’s top culinary professionals, Sakai knives are more than tools—they are the living legacy of over 600 years of master craftsmanship.

-

At KIREAJI, we work directly with the Shiroyama Knife Workshop in Sakai, Japan, ensuring every blade is hand-forged, finished to perfection, and shipped straight from the workshop to kitchens across the globe. No middlemen. No mass production. Only authentic, artisan-made knives, crafted to elevate your cooking for a lifetime.