-

Sakai Traditional Craftsmen Collection

-

The Japanese knives crafted by the artisans of Sakai City boast over 600 years of history and tradition. We promise to deliver this exceptional quality to our customers.

-

In Sakai City, only 28 traditional craftsmen carry the responsibility of preserving Japan's proud heritage of craftsmanship. These artisans earn the prestigious title of traditional craftsman after more than 12 years of hands-on experience and passing stringent examinations. The knives they create represent centuries of skill and tradition. Compared to mass-produced alternatives, knives forged by KIREAJI’s traditional craftsmen offer superior quality and practicality, and the title of traditional craftsman has become a symbol of trust for those seeking true craftsmanship.

-

Traditional industries are founded on the accumulation of skills, passed down through generations and learned through dedicated practice with both hands and body. These techniques cannot be conveyed through words alone; they are refined over time, through years of experience and intuition. Today, more than ever, we recognize the immense challenges of preserving these traditions.

-

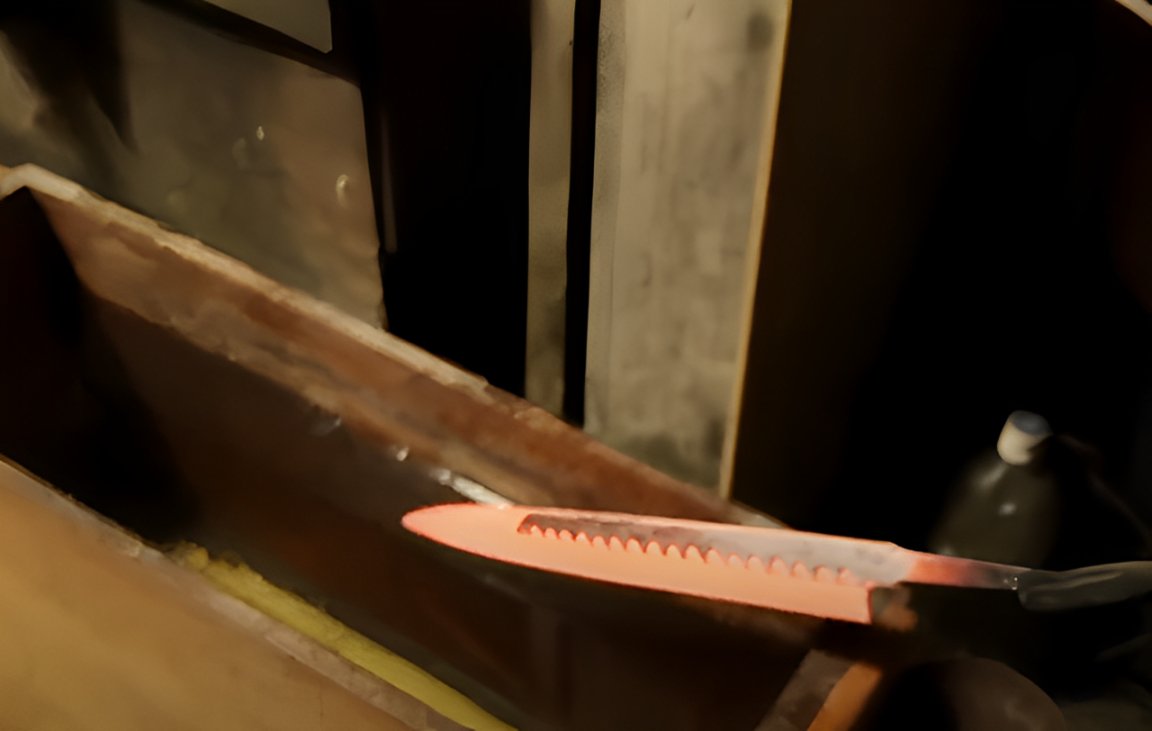

The Art of the Blacksmith: The Beauty of Steel Born from Fire

-

A blacksmith is a skilled artisan who possesses advanced techniques and traditional craftsmanship in handling metal. Their work transcends mere metalworking; it is an artistic process that breathes life into the material. The craft of blacksmithing cannot be mastered overnight; it requires years of training to achieve true mastery. Blacksmiths heat metal, forge it with hammers, and shape it to enhance its strength, creating works that seem to come alive.

-

The path of a blacksmith is rigorous, demanding constant effort in a challenging environment. They heat steel to high temperatures and strike it with hammers, transforming the metal. This process requires not only strength but also sensitivity and focus. No matter how experienced a blacksmith may become, each task presents a new challenge, leading to the deepening of their craft.

-

Moreover, blacksmiths bear the responsibility of passing down the knowledge and skills they acquire to the next generation. Their commitment to preserving tradition while continuously pursuing innovation enhances their craft. Many artisans establish their own unique styles and techniques while growing through mutual encouragement and competition among peers.

-

For a blacksmith, the goal is not just to create high-quality tools but to produce works that resonate with the hearts of those who use them. They transform cold iron into beautiful pieces of art through fire and forging. At the moment when the cold steel meets the heat of the flames, the passion and skill of the blacksmith come to fruition.

Forging

For the sake of sharpness, we discern even the slightest variations in color.

-

The defining characteristic of Sakai knives, and Japanese knives in general, is the technique of combining soft iron with steel and hardening it through a heat treatment process. When attaching the steel to the blade, proper temperature control is crucial. The temperature for attaching the steel to the soft iron is around 1000 degrees Celsius, but if stretched at this temperature, the steel can become damaged. Therefore, it is essential to lower the temperature to around 800 degrees Celsius before stretching the blade. This temperature management greatly impacts the quality of the knife.

-

For a blacksmith, temperature control is of utmost importance as it directly affects the knife's longevity. When crafting tools, I always strive to infuse my work with dedication and create knives that fully satisfy their users, regardless of the circumstances.

Shogo Yamatsuka

Japanese Knife Ginsan Craftsmanship

- Mr. Yamatsuka was recognized in 2012 as a traditional craftsman with excellent forging skills in the Sakai blade-making sector.

- He is a craftsman in Sakai, rare for his mastery of Ginsan steel.

Satoshi Nakagawa

Japanese Knives by the Youngest Traditional Craftsman in History

- At the age of 30, his craftsmanship in producing high-quality knives was recognized, and he was officially certified as a traditional craftsman by the Sakai Chamber of Commerce and Industry in 2022.

- Nakagawa is sought after by top chefs, both Japanese and Western, and plays a pivotal role in supporting the industry.

Keijiro Doi

A Master's Legacy

- Mr. Doi, born in 1927, began his career as a blacksmith at 19, following in the footsteps of his father, Kazuo Doi, a master craftsman in Sakai. He retired in 2012 and passed away in 2017.

- His knives are no longer being produced, making them extremely valuable.

Tadashi Enami

Tradition Meets Innovation in Japanese Knives

- Certified as a traditional craftsman in 2003 after a rigorous examination by the Sakai Chamber of Commerce and Industry.

- Enami Cutlery Workshop, a blacksmith with over 600 years of tradition in Sakai, is led by Tadashi Enami, the fifth-generation traditional craftsman.

Yuzan

Legendary Traditional Craftsman of Japanese Knife: The Father of Traditional Craftsman Shogo Yamastuka

- Yuzan is the father of traditional craftsman Shogo Yamatsuka.

- Yuzan was a craftsman who exclusively worked on Mizuyakii among Honyaki. These Japanese knives are extremely rare and hardly available on the market.

Kenichi Shiraki

Master of Sakai Forged Knives

Kenichi Shiraki was a highly skilled blacksmith, certified as a traditional craftsman, known for his mastery of Sakai's traditional knife-making techniques. Shiraki's legacy continues through his sole apprentice, Satoshi Nakagawa, who trained under him for 16 years and founded Nakagawa Cutlery in 2021. Shiraki has retired, making his knives rare and highly sought after.

Tatsuo Ikeda

Master Craftsman Whose Knives Embody Skill and Passion

- 1954: Began his journey as a blacksmith.

- 1985: Certified as a Traditional Craftsman by the Minister of International Trade and Industry.

- 1993: Awarded the Director-General of the Science and Technology Agency Award for developing the Mon-Tanren technique.

- 2009: Honored with the Order of the Sacred Treasure, Silver Rays, by the Emperor of Japan.

Yoshikazu Ikeda

A Master Preserving Tradition and Shaping the Future

- Mr. Ikeda began knife making in 1967 under his father’s guidance. In 1983, he founded "Ikeda Tanrensho" with his brother. Recognized as a Traditional Craftsman in 1988, he has received numerous awards, including the Osaka Prefecture Outstanding Artisan Award in 2014.

- Renowned for his exceptional skill, he remains dedicated to preserving traditional Japanese knife forging.

A knife is a lifelong investment. Since it reflects the craftsmanship of the artisan, the daily dedication to knife-making is essential.

Japanese knives are not just cooking tools; they are works of art that embody the skill, passion, and culture of the artisans. Each knife is handcrafted and designed to fit comfortably in the user’s hand. Every time you use a knife, you hone your cooking skills and learn to bring out the essence of the ingredients. This accumulation of experience adds depth to your cooking and helps to unlock the true flavors of the food.

-

The Craft of a Blade Sharpener: Skill and Passion in Mastery

-

A blade sharpener is not just a technician but a specialist with craftsmanship honed through years of training and experience. The art of sharpening is not something that can be mastered overnight; it requires decades of practice to achieve true expertise. It begins with observation and learning from a mentor, gradually building skills through hands-on experience, embracing both failures and successes along the way. Often, young apprentices start under the guidance of a master, learning by watching, and eventually establish their own style through independence.

-

The long journey of becoming a sharpener is a testament to patience and a desire for improvement. Craftsmen devote themselves daily to perfecting their knives, tailoring each sharpening to the knife's condition and type. No matter how experienced a craftsman may become, each day presents a new challenge. Every knife possesses unique characteristics, requiring the sharpener to maintain focus and delicate sensitivity to achieve the best results.

-

Moreover, success as a sharpener is built not only on individual skill but also through the camaraderie and competition among fellow artisans. Competing with peers and uplifting one another sharpens both technique and pride. This competition among craftsmen results in high-quality knives delivered to chefs and households around the world.

-

For a blade sharpener, there is only one goal: to continue creating knives with the finest cutting performance. The sharpeners supporting Japanese knife culture do not merely grind steel; they pour tradition, technique, and heart into every single knife they finish.

-

For a blade sharpener, there is only one goal: to continue creating knives with the finest cutting performance. The sharpeners supporting Japanese knife culture do not merely grind steel; they pour tradition, technique, and heart into every single knife they finish.

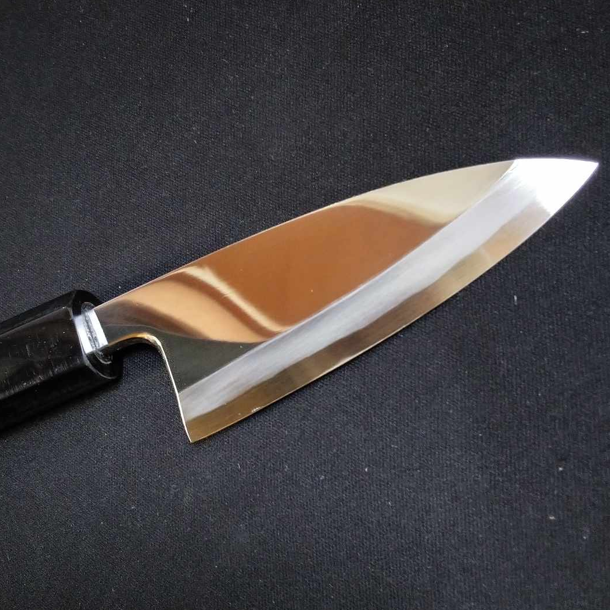

Sharpening

For the sake of sharpness, we hone down to microns.

-

The skills of traditional craftsmen and sharpeners in Sakai City are highly regarded around the world. Sakai knives, with over 600 years of history, are known for their exceptional sharpness and durability. The existence of skilled sharpeners supports this quality.

-

Each knife crafted by Sakai sharpeners is the result of meticulous, dedicated craftsmanship. Their skills and passion weave a story into each blade, and this allure can only be fully appreciated when held and used.

-

Knives created by the traditional craftsmen of Sakai City are an invaluable companion for anyone who enjoys cooking.

Tadayoshi Yamatsuka

Master of Japanese Knife Mirror Polishing

- Mr. Yamatsuka was recognized as a traditional craftsman in 2022.

- Renowned in Sakai for his mirror polished technique on Japanese knives.

Shotaro Nomura

The Craftsmanship and Beauty of Sakai Knives

- Started his career in 1962 and was certified as a Traditional Craftsman in 1988.

- Mr. Nomura trained at the well-known Ino Hamono in Sakai City, where he dedicated himself to mastering the art of sharpening. Over the years, he has become a steadfast guardian of Sakai's tradition, carrying forward techniques passed down through generations.

How Traditional Japanese Knife-Making Skills Are Passed Down

-

A Legacy Built Through Apprenticeship and Dedication

In the city of Sakai, the tradition of Japanese knife-making has been preserved and refined for centuries. This legacy is not sustained by manuals or textbooks, but through hands-on training, observation, and mentorship. The foundation of skill transmission lies in a time-honored apprenticeship system, where young craftsmen learn directly under experienced masters through years of disciplined practice.

-

Historically, the city and local knife associations established formal training centers for aspiring artisans to learn the basics. Even today, skills are passed down through these long-term apprenticeships, where daily repetition, attention to detail, and the spirit of craftsmanship are nurtured.

-

Learning by Watching: The Power of Observation and Oral Tradition

In traditional Japanese craftsmanship, skills are often transmitted through kuden (oral instruction) and mite nusu me—a phrase that literally means “steal by watching.” This method emphasizes observing the master’s techniques and intuitively grasping the delicate hand movements, rhythm, and sensitivity that define true craftsmanship.

-

Since many of the processes are still performed manually, mastering the subtle physical nuances—such as pressure, angle, and timing—is crucial. These are things that cannot be fully captured in writing or diagrams, making direct, in-person learning essential.

-

Support from the Community: Nurturing the Next Generation

The survival of this craft isn't left to tradition alone. The city of Sakai and industry organizations actively support skill transmission through subsidies, training programs, and certification systems such as the Dento Kogeishi (Traditional Craftsman) designation. This not only helps young artisans set clear goals but also enhances the social recognition of their work.

-

Thanks to these systems, the transition from novice to skilled craftsman is guided and supported, ensuring the continuation of high standards within the knife-making industry.

-

Education Through Experience, Not Classrooms

While systematic education through vocational schools is limited, real-world training under a master remains the primary route to becoming a craftsman. However, community outreach programs—including public workshops and factory tours—have helped spread awareness of the craft’s value among younger generations and the general public.

-

Preserving Unchanging Techniques in a Changing World

The techniques used in making Sakai knives have remained largely unchanged. Traditional hand-forging methods, natural whetstone sharpening, and careful handle fitting are still practiced today. Craftsmen continue to use traditional materials, such as straw for annealing and pine charcoal for water quenching, to maintain the integrity of the process.

-

These time-honored techniques, passed down through generations, are not preserved for nostalgia—they are preserved because they consistently produce knives of unparalleled quality. The pride that craftsmen take in their work forms the backbone of Sakai’s global reputation.

-

Conclusion — A Tradition Sustained by People and Community

The traditional craftsmanship of Sakai’s Japanese knives is sustained through a unique blend of long-term apprenticeship and the oral and observational techniques that have been passed down for generations. This is more than just skill transfer—it is a human connection built on trust, patience, and mutual respect.

-

At the same time, support from the local community and government organizations plays a vital role in keeping this heritage alive. With financial aid, training opportunities, and recognition programs, young artisans are given the tools and motivation to carry the torch forward.

-

Most importantly, the unchanging commitment to handcraftsmanship continues to define every knife made in Sakai. In a rapidly changing world, this dedication to tradition ensures that these knives retain their authenticity, quality, and cultural value. Backed by skill, pride, and the support of an entire community, the legacy of Sakai’s knife-making will continue to thrive for generations to come.

Sakai's Declining Japanese Knife Craftsmen

Sakai's esteemed cutlery tradition, renowned for its sharpness and craftsmanship, is at risk with only a dozen blacksmiths remaining. Facing competition and declining interest, strategies such as exploring new markets and fostering youth interest are vital for survival. This situation underscores a broader challenge in cultural preservation. Supporting Sakai’s craftsmen is crucial to maintaining this legacy.

The Origin of Craftsmanship

-

The Artisan's Creed: Surpassing the Master

-

In the world of traditional craftsmanship, it is not enough to simply refine one's skills. The ultimate goal is to surpass the master. This is not just about achieving technical superiority; it is about creating new value that transcends the techniques and spirit instilled by the master.

-

When I began my journey, I could only follow in my master's footsteps. However, as I delved deeper into the art, I realized that merely imitating was insufficient. To "surpass" is to embody respect and gratitude for the master while pushing one's own abilities to their limits. It also carries the responsibility of inspiring the next generation with greater possibilities.

-

As a craftsman, I approach every knife I forge not as a mere tool, but as a crystallization of tradition and dedication. With this in mind, I return to the forge each day, ready to push boundaries further.

-

To those reading this, I want to share that every handcrafted piece bears the mark of such challenges and passion. Understanding this background can deepen your appreciation for the tools you hold in your hands.

-

Beware of Inexpensive Knives

Inexpensive knives are often made with cost-cutting measures during production. Specifically, important elements such as sharpness, balance, and maintainability—key factors that directly affect quality—are not given sufficient investment. These aspects are often difficult to notice at first glance, but they can significantly impact the performance of the knife.

-

At KIREAJI, we offer authentic Japanese knives crafted by trusted artisans from Sakai City. Every knife is carefully handcrafted with a focus on sharpness, balance, and maintainability, ensuring you receive a high-quality product that provides long-lasting reliability and peace of mind.