Japanese Knife Structure

-

Inside the Blade: The Unique Structure of Japanese Knives

Discover the extraordinary design behind traditional Japanese knives.

From single-bevel geometry to Kasumi and Honyaki construction, this video explores how structure shapes sharpness, durability, and beauty.

Learn why understanding the anatomy of a Japanese knife can elevate your cooking—and your respect for craftsmanship. -

1. Single vs. Double-Edge Knives: Where Craftsmanship Meets Functionality

-

Across kitchens worldwide, two distinct knife philosophies have taken shape—the refined precision of Japanese single-edge blades and the practical versatility of Western double-edge knives. Their differences go beyond design; they reflect deep-rooted values about food, technique, and craftsmanship.

-

-

1-1. Single-Edge Knives: Precision Born from Japanese Tradition -

Japanese single-edge knives are celebrated for their elegance and exacting craftsmanship. As the name implies, only one side of the blade is sharpened, creating a uniquely refined geometry defined by the ridge line known as the Shinogi.

-

What Makes Single-Edge Knives Unique?

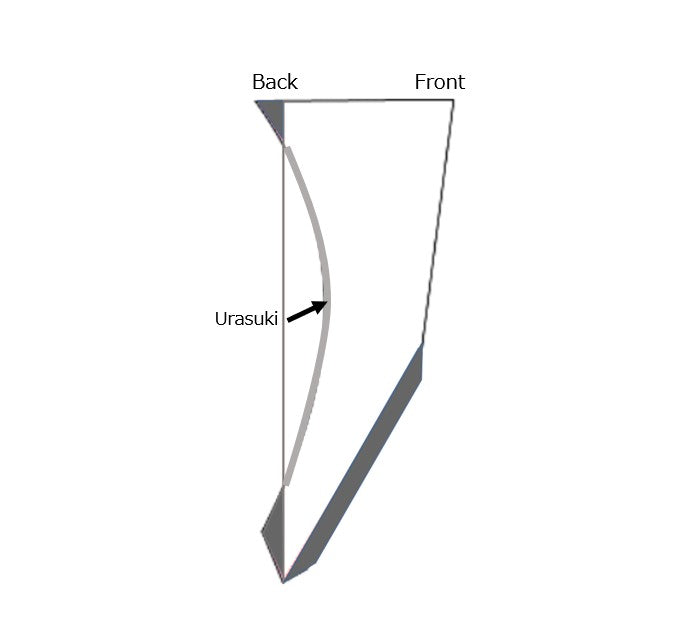

Unlike double-edge knives, single-edge blades are asymmetrical. The front (right) side is ground at a sharp angle, while the back has a subtle hollow—called urasuki—that enhances cutting precision and allows food to separate smoothly from the blade.

Thanks to this design, the blade tapers to an extremely thin and sharp edge. During cutting, a small air pocket forms, helping ingredients glide off the knife with ease.

-

Advantages

- Exceptional Sharpness

Ultra-thin edge glides through ingredients with minimal resistance, producing clean cuts without crushing fibers—ideal for sashimi or delicate vegetables. - Simplified Sharpening

Only one side needs sharpening, allowing for more consistent angles and easier maintenance. - Purpose-Driven Design

Each knife has a clear role: Deba for fish butchering, Yanagiba for sashimi, Usuba for vegetables.

- Exceptional Sharpness

-

Disadvantages

- Requires Skilled Technique

The asymmetry means mastering straight cuts takes practice. A proper grip and awareness of the blade’s curve are essential. - Limited for Left-Handed Users

Standard single-edge knives are made for right-handed users; left-handed versions must be custom-made or specially sourced.

- Requires Skilled Technique

-

1-2. Double-Edge Knives: Western Practicality and Balance -

Double-edge knives are sharpened symmetrically on both sides, creating a balanced structure that suits a wide range of cutting styles. Popular types like Santoku and Gyuto are staples in both Western and Japanese households today.

Structure and Practical Strength

With blades ground on both sides, double-edge knives are intuitive to handle and versatile across tasks—from slicing meat to chopping vegetables. Their balanced design helps maintain control even through tougher ingredients.

-

Advantages

- Handles Hard Foods Well

Even pressure on both sides provides stability for dense ingredients like pumpkin or potatoes. - Ambidextrous Use

The symmetrical shape works equally well for right- and left-handed users. - All-Purpose Utility

One knife can handle meat, fish, and vegetables—perfect for fast-paced, everyday cooking.

- Handles Hard Foods Well

-

Disadvantages

- Less Ideal for Thin Slices

The dual-beveled edge makes it harder to achieve ultra-thin cuts like those required for sashimi. - Sharpening Takes Practice

Maintaining symmetry when sharpening requires precise angle control on both sides—making it trickier for beginners.

- Less Ideal for Thin Slices

-

2. How East and West Cut Differently: The Culture Behind the Blade -

The Beauty of Pull-Cutting: A Glimpse into Japanese Cutting Philosophy

In Japanese cuisine, a knife is not just a tool—it’s a brush that paints the natural beauty of ingredients. Among its most revered techniques is “hiki-giri”, or pull-cutting. This elegant method, often used with yanagiba knives, slices through delicate fish in a single stroke, preserving the structure of the fibers and revealing mirror-like surfaces. It’s not just about cutting—it’s about honoring the ingredient.

-

Contrasting Ideals: Efficiency in Western Cooking

While Japanese cuisine emphasizes precision and presentation, Western culinary tradition values speed and versatility. Here, the knife is a multitool—expected to cut through meat, vegetables, and herbs alike. The double-edge blade, symmetrical and robust, reflects this need for practicality, allowing chefs to move quickly and intuitively between tasks.

-

Choosing the Right Knife for the Moment

Both philosophies have their place in modern kitchens. The key is matching the knife to the task and the cook’s intent.

-

When Single-Edge Knives Shine:

- Preparing sashimi or dishes where visual appeal is essential

- Decorative vegetable cuts or precise garnishing

- Filleting fish or tasks requiring technical finesse

-

When Double-Edge Knives Excel:

- Everyday prep work across various ingredients

- Quick, efficient slicing, chopping, and dicing

- Cooking routines for all skill levels, from beginner to pro

-

Skill Level and Knife Choice

For those new to Japanese knives, starting with a double-edge knife like a Santoku offers familiarity and flexibility. As your interest grows—or as you specialize in sushi, fish, or vegetable techniques—you may find yourself drawn to the precision of yanagiba or deba knives.

More advanced cooks often build a collection, choosing different knives for different ingredients and occasions—not just out of utility, but out of reverence for the craft.

-

A Cultural Heritage in Your Hands

Japanese single-edge knives are not merely sharpened steel—they’re works of art, shaped by centuries of tradition and the hands of master craftsmen. Western double-edge knives, on the other hand, represent practical innovation, built for efficiency and adaptability.

In today’s global kitchen, understanding both traditions allows cooks to select tools with purpose, meaning, and skill.

Your choice of knife reflects your philosophy—whether it leans toward artistic perfection or efficient mastery. In embracing both, we carry forward the wisdom of East and West, one slice at a time.

3. Understanding Japanese Knife Craftsmanship: Materials, Methods, and Meaning

-

When it comes to Japanese knives, the differences go far beyond the edge.

The way each knife is made—its materials, structure, and forging method—reflects a deep philosophy rooted in centuries of craft.

For culinary enthusiasts, understanding these distinctions is essential to fully appreciating the artistry and function of Japanese blades. -

3-1. Single-Edge Knives: Honyaki vs. Kasumi

-

-

Honyaki: Pure Steel, Pure Precision

Forged from a single piece of high-carbon steel, Honyaki knives are the ultimate expression of traditional Japanese forging. Directly descended from katana-making techniques, they offer exceptional hardness, fine edges, and an unmatched level of sharpness.

However, this precision comes with demands.

Their extreme hardness makes sharpening more challenging, requiring proper whetstones and refined technique. They're also more brittle, meaning careful handling is essential. Because the process is so intricate, quality varies greatly depending on the craftsman’s skill. -

Kasumi (Awase): Practical Harmony

In contrast, Kasumi knives are forged by laminating a hard steel core with soft iron, achieving a balance between performance and practicality. Their relative ease of sharpening and more forgiving structure make them suitable for both professionals and serious home cooks.

However, the bond between dissimilar metals may lead to warping over time, and improper craftsmanship can affect long-term performance. Still, when well made, Kasumi knives beautifully combine tradition and accessibility.

-

3-2. Double-Edge Knives: Zenkou vs. Kasumi Hari Awase

-

Zenkou (All Steel): Durable and Precise

Made entirely from one piece of steel, Zenkou knives—or all-steel knives—offer strength and precision.

They resist chipping, hold their edge longer, and are suitable for both professional and heavy home use. Their uniform structure also makes them appropriate for single-bevel sharpening if desired.On the downside, their hard composition means sharpening takes time and skill, and without softer support layers, they are more vulnerable to impact damage. Additionally, using high-quality steel throughout raises production costs.

-

Kasumi Hari Awase: Layered Craftsmanship

Also called multi-layer knives, Kasumi Hari Awase knives are typically constructed with a three-layer structure: a hard steel core sandwiched between softer outer metals.

This design improves shock absorption, durability, and sharpening ease, making them ideal for daily use and a wide range of users.However, the soft outer layers can be prone to deformation under pressure, and edge retention may fall short compared to all-steel knives. Because of their double-bevel construction, they are also not suited for traditional Japanese single-bevel techniques.

FAQ About Single-Edged and Double-Edged Knives

01. What is the difference between single-edged and double-edged knives?

Single-edged knives have the blade sharpened on only one side, with the opposite side flat or slightly concave. This traditional design, often found in Japanese wa-bocho, allows for unparalleled precision and beautiful, clean cuts.

In contrast, double-edged knives are sharpened symmetrically on both sides—a design widely seen in Western and Chinese knives. Their versatility makes them ideal for a wide range of ingredients and cutting styles.

02. Why did single-edged knives evolve in Japan?

The development of single-edged knives reflects Japan’s pursuit of culinary delicacy and precision. These knives were especially refined for preparing fish, enabling flawless cuts that preserve both the structure and natural flavor of delicate ingredients.

Japan's long history of sword-making also influenced the fine craftsmanship seen in these blades.

03. Which type is recommended for beginners?

For those new to cooking or Japanese knives, double-edged knives are generally recommended. Their symmetrical design makes them:

・Easier to sharpen

・More intuitive for beginners

・Suitable for a wide range of cuisines

・Accessible to both left- and right-handed users

・Typically more affordable than handcrafted single-edged knives

04. Are cutting techniques different between single-edged and double-edged knives?

Yes, the techniques differ significantly:

Single-edged knives:

・Emphasize pull-cutting (hiki-giri)

・The blade is held perpendicular to the ingredient

・Cuts are performed in a single, fluid motion

・Reduces damage to delicate ingredient fibers

Double-edged knives:

・Allow both push-cutting and pull-cutting

・Back-and-forth motion is common

・Accommodate diverse cutting techniques for different ingredients

05. Can left-handed people use single-edged knives?

Yes, but they require special left-handed versions.

Standard single-edged knives are crafted for right-handed users. Using them with the left hand causes the blade to pull away from the ingredient, making precise cutting difficult.

Left-handed single-edged knives reverse the blade orientation, ensuring the same level of precision and control.

Ⅰ. Why Are Japanese Knives Single-Edged?

-

A Thousand Years of Craftsmanship Behind the Blade

-

In Japan, a blade is more than just a tool.

It reflects history, pride, and the pursuit of perfection.

And nowhere is that more visible than in the design of Japanese single-edged knives.Why are they made this way?

The answer lies not only in cooking but in centuries of tradition, peace, and craftsmanship. -

(1) Blades Were Never Just for Battle

In Japan, blades have always been more than weapons.

They were seen as symbols of pride, beauty, and technical mastery.One key figure in this story is Emperor Go-Toba, born in 1180 during Japan's Kamakura period.

He became emperor at just three years old and later ruled as a cloistered emperor.But Go-Toba was no ordinary ruler—he had a deep passion for blades.

He supported swordsmiths across Japan and even participated in forging swords himself.This deep cultural respect for blades became part of Japanese identity—and eventually shaped the knives used in Japanese kitchens today.

-

(2) Peace Perfected the Blade

During Japan’s Edo period, the country experienced over 260 years of peace.

Without wars to fight, blacksmiths focused on new challenges—making tools for daily life, especially kitchen knives.Chefs, too, devoted themselves to turning cooking into an art form.

Without peace, neither Japanese cuisine nor the tools that support it could have reached such heights of refinement. -

-

(3) The Turning Point — From Swords to Knives

In 1876, Japan issued the Haitōrei, banning people from carrying swords in public.

Many swordsmiths lost their livelihood—but not their skills.They redirected their craftsmanship toward making kitchen knives, transforming towns like Seki and Sakai into global centers of blade production.

The same techniques used for legendary samurai swords now lived on—in Japanese knives. -

Why Single-Edged?

The answer is simple: beauty and precision.

A single-edged blade allows chefs to separate fish from bone with clean, flawless cuts, and slice meat along its natural fibers without damaging the texture.

The shape remains perfect, the flavor untouched, the presentation beautiful.In Japan, where food is treated as art, the single-edged knife was not just practical—it was essential.

-

A Knife That Reflects a Nation

A Japanese knife is not just a kitchen tool.

It is a product of history, peace, craftsmanship, and cultural pride. -

Every cut tells a story—of ancient emperors, master swordsmiths, peaceful centuries, and the pursuit of perfection.

The single-edged blade is more than a technical feature.

It is a reflection of what makes Japanese culture unique.

Ⅱ. Is Your Knife a "Versatile Partner" or a "Specialized Craftsman"?

-

Pick up the knife in your kitchen. Is it a "reliable all-rounder" that can handle various ingredients with a single blade? Or is it a "specialized expert" designed for specific tasks?

This difference reveals the fundamental design philosophy gap between Japanese and Western knives.

-

-

Japanese Knives: The Craftsman's World of "Pursuing One Perfect Thing"

What Japanese Knives Aimed to Achieve

Japanese knives inherited Japanese sword techniques and evolved specifically for fish and vegetable preparation. Since Japanese cuisine values not crushing food cells and creating beautiful cross-sections, knives required ultimate sharpness and delicacy.

-

Characteristics of Japanese Knives:

- Single-edged structure: Good separation from ingredients, achieving beautiful cuts

- Specialized focus: Evolved for specific purposes like yanagiba (for sashimi), deba (for fish), and usuba (for vegetables)

- Ultimate sharpness: Razor-sharp edge that doesn't crush food cells

- Insert-style handle: Sustainable design where handles can be replaced when they rot

-

The Aesthetic of "Sharpening Culture"

Japanese people have a culture of "treasuring knives like swords". They regularly sharpen them to maintain their edge and use a single knife for decades. This transcends mere attachment to tools—it's a uniquely Japanese aesthetic.

-

Japanese Cuisine Approach: "Respect for Ingredients and Pursuit of Beauty"

- Cooking as art: Maximizing the beauty and flavor inherent in ingredients

- Ingredients as protagonist: Especially in sashimi, where knife sharpness affects taste

- Delicate technique: Precise cutting that doesn't crush food cells

-

Western Knives: Universal Practicality Born from the "Pursuit of Efficiency"

What Western Knives Aimed to Achieve

Western knives, introduced to Japan from the West after the Meiji period, developed against the backdrop of a meat-eating culture. Since Western cuisine involves boldly cutting meat with bones and preparing meat dynamically in stewed dishes, knives needed durability and versatility.

-

Characteristics of Western Knives:

- Double-edged structure: Symmetrical design that's easy for anyone to handle

- One knife, multiple roles: Versatility to handle meat, fish, and vegetables with a single blade

- Robust construction: Strength and durability to cut through bone-in meat

- Handle structure: Sturdy construction with the blade's core material sandwiched in the handle and secured with rivets

-

"Practicality-First" Rational Design

Historically, Western knife culture has emphasized "efficiency and practicality". When blades deteriorated, the tendency was to choose replacement with new tools rather than resharpening. This was a rational decision prioritizing time efficiency, not a disregard for quality.

-

Western Cuisine Approach: "Efficient Nutritional Intake"

- Cooking as means: Quickly and efficiently creating nutritious meals

- Completion through seasoning: Final flavor adjustment with sauces and spices

- Powerful cooking: Practicality to boldly process even bone-in meat

-

Fundamental Differences in Culinary Philosophy

The contrast between these two approaches reveals not just different tools, but entirely different relationships with food and cooking.

-

Modern Impact: Fusion and Evolution

Interestingly, the santoku knife most commonly used in Japanese homes today is actually a type of Western knife. This is a uniquely Japanese evolution born from fusing the gyuto (chef's knife) with Japanese knife techniques.

There are also double-edged Japanese knives (like nakiri knives) and Japanese-made Western knives (Japanese santoku, Japanese gyuto, Japanese petty knives), making the boundaries complex and intertwined.

-

The Worldview Embedded in a Single Knife

When you hold a Japanese knife, you're gripping the "crystallization of a thousand years of craftsmanship and aesthetic sense". It's an artwork that embodies respect for ingredients and the aspiration for the perfect cut.

When you hold a Western knife, you're gripping an "efficient and practical universal tool". It's a reliable partner perfectly adapted to modern lifestyles.

-

What's Your Cooking Style?

- Pursuing ingredient beauty and caring about sharpness → Japanese knife specialization

- Time-saving, efficiency-focused, wanting one knife to handle everything → Western knife versatility

- Wanting both benefits → Japanese-made Western knives as an option

-

In the next section, we'll examine in detail how this philosophical difference manifests in "blade structure". The difference between single-edge and double-edge isn't merely a shape difference—it's the difference in approach to cooking itself.

Ⅲ. The Mystical Technology of Japanese Knives: Three Precision Structures That Captivate the World and the Depths of Japanese Culinary Culture

-

Japanese knives are coveted by chefs worldwide. Behind their exceptional sharpness lie three precision technologies refined over centuries. These wa-bocho (Japanese knives), which transcend mere cooking tools to become works of art, capture the hearts of culinary professionals around the globe. But what makes them so captivating?

-

The Special Technology of Japanese Knives: Three Innovations Born from Craftsman's Wisdom

-

The phenomenal performance of Japanese single-edge knives is achieved through three precision technologies: tapering,angle variation (twist), and urasuki (back hollowing). These form a sophisticated system where each element works in harmony with the others, creating effects impossible to achieve individually.

-

The Precision Structure of Single-Edge Knives: Fusion of Science and Art

-

(1) Tapering: Mastering Friction Through Minute Thickness Changes

The Miracle of Tapering

Japanese knife blades feature a "tapering" structure that gradually thins from heel to tip. This subtle thickness variation creates microscopic gaps between the food and blade during cutting, dramatically reducing friction.

- Smooth Cutting Sensation: Both push-cuts and pull-cuts can be performed without resistance

- Food Protection: Preserves the original texture of ingredients without crushing fibers

- Freshness Preservation: Prevents deterioration from frictional heat, maintaining ingredient beauty on the plate

-

tapering

Exquisite Balance Through Craftsmanship

Adjusting this tapering relies on the delicate sensibilities of skilled bladesmiths. Excessive tapering compromises durability, while insufficient tapering reduces sharpness. This exquisite balance represents the essence of Japanese knives.

-

(2) Angle Variation (Twist): Calculated Angle Design

The Secret of Angles

Japanese knife edges feature subtle angle changes from heel to tip. This "twist" technology achieves optimal sharpness for specific applications.

-

Specific Angle Design Examples:

- Yanagiba Knife: Heel 13° → Tip 11° (achieving beautiful sashimi cuts)

- Usuba Knife: Heel 10° → Tip 8° (handling delicate vegetable cutting)

-

The Importance of Sharpening

Maintaining these angle variations is essential for preserving knife performance. Without proper sharpening techniques, this precision design loses its meaning.

-

(3) Urasuki: The Greatest Innovation of Japanese Knives

Concave Structure Creating Phenomenal Sharpness

The "urasuki" concave structure applied to the back surface of single-edge knives is truly the hallmark technology of Japanese knives. This design minimizes contact area with food, achieving ultimate sharpness.

-

Effects of Urasuki:

- Friction Minimization: Extremely small contact area enables smooth cutting

- Flavor Protection: Particularly vital for sashimi, preserving the delicate umami of fish

- Point Contact Achievement: Ideal cutting state where only one point of the blade touches the ingredient

-

urasuki

Precision Processing Technology

Creating proper urasuki requires advanced technique and experience. Too wide compromises strength, too narrow reduces effectiveness, demanding exceptional craftsman skill.

-

Why These Technologies Emerged: Deep Connection with Japanese Culinary Culture

-

Supreme Respect for Ingredients

The fundamental philosophy of Japanese cuisine—"maximizing the beauty of ingredients"—gave birth to these precision technologies. Fresh fish sashimi, seasonal vegetable thin slices—in these dishes, the beauty of the cut surface itself becomes part of the flavor.

-

Fusion of "Ma" Aesthetics with Technology

The uniquely Japanese concept of "ma" (negative space) is reflected in knife technology. The microscopic space between ingredient and blade, the rhythm created by angle changes, the point contact from urasuki—all of these form the technological foundation supporting Japanese cuisine's delicacy.

-

Adaptation to Seasonal Ingredients

To handle the diverse ingredients nurtured by Japan's rich four seasons, knives also diversified. Spring bamboo shoots, summer sea eel, autumn saury, winter pufferfish—knife design philosophy optimized for each ingredient developed these precision technologies.

-

Inheritance of Craftsman Culture

Japan's craftsman culture tradition of "skill inheritance" has continuously refined these technologies across generations. The accumulation of minute techniques passed from master to apprentice has created today's sophisticated Japanese knives.

-

Universal Appeal to the World

-

Today, chefs specializing in French and Italian cuisine are also captivated by Japanese knives. This is because the sharpness created by these technologies holds universal value transcending culinary genres.

Respect for ingredients, pursuit of technical excellence, quest for beauty—these are universal values shared by chefs worldwide. Japanese knife precision technology serves as the ultimate tool for materializing these culinary aspirations, continuing to be beloved across borders.

Chefs around the world, please try holding a Japanese knife at least once. Its phenomenal sharpness will surely bring a new dimension to your cooking. Together with the Japanese spirit embedded in the technology, why not expand the possibilities of your cuisine?

The three precision structures of Japanese knives—tapering, twist, and urasuki—represent more than technical achievements. They embody centuries of cultural refinement and the relentless pursuit of culinary perfection that defines Japanese craftsmanship. In a world where cuisine knows no borders, these tools serve as bridges connecting different culinary traditions through their universal language of exceptional performance.

Ⅳ. The Difference Between Honyaki and Zenkou (All Steel) Knives

-

-

Knives made from a single piece of hard steel come in two distinct types: Honyaki and Zenkou (All Steel). Understanding these differences is crucial when choosing a knife.

-

Firstly, Honyaki refers to knives created through forging, a meticulous process where steel is repeatedly hammered and shaped. This method is reminiscent of traditional Japanese sword-making, where artisans use their skill to craft each knife by hand. Forging involves heating the metal and shaping it with a hammer, aligning the internal crystal structure and compressing it. This process imparts exceptional durability and toughness to the blade, which is crucial for withstanding impact and stress. A Honyaki knife, forged in this manner, boasts remarkable hardness and sharpness, even allowing thin blades to cut through food effortlessly. Its precision ensures that the edge remains sharp for an extended period, minimizing the need for frequent sharpening. This is the essence of craftsmanship in Honyaki knives.

-

A Honyaki knife is not just a tool but a piece of artistry imbued with the skill and passion of the craftsman. The sensation of the blade gliding through ingredients, the beauty of the precise cuts, and the lasting sharpness offer an unparalleled experience. For those who value the art of cooking, a Honyaki knife elevates both the preparation and presentation of food, making it a prized choice for professionals and enthusiasts alike.

-

In contrast, Zenkou (All Steel) knives are made from a single piece of steel that is simply shaped using a mold. These knives lack the forging process, which results in a less refined internal structure, leading to lower durability and toughness compared to Honyaki knives. However, Zenkou (All Steel) knives are cost-effective and suitable for everyday use.

-

Honyaki knives, with their special technique and craftsmanship, offer unmatched beauty and performance. For those seeking a superior knife, Honyaki provides an exceptional option that stands out from the rest.

The Origin of Craftsmanship

-

The Elegance of Japanese Knives

Japanese knives are renowned for their precision and artistry. One of their defining characteristics is the tapered design, or "teppā", which creates a gradual reduction in thickness from the spine to the edge. This meticulous craftsmanship not only contributes to the knife’s sharpness but also ensures minimal resistance when slicing through ingredients.

Additionally, Japanese knives often feature a single-beveled edge, which provides unparalleled control and accuracy. This design, combined with a hollow grind on the reverse side (Urasuki), minimizes the surface area that comes into contact with the food. As a result, flavors remain intact, textures stay true, and each slice becomes a culinary experience.

-

Appreciating Both Worlds

While Japanese knives excel in precision and artistry, Western knives provide strength and adaptability. Rather than viewing them as competitors, we should celebrate their unique strengths and recognize how they complement different cooking styles.

By understanding the philosophy behind their design, one can fully appreciate the culinary heritage and craftsmanship that each type represents. After all, the knife you choose is not just a reflection of your cooking needs but also a testament to your respect for the ingredients and the art of cuisine.

-

As a craftsman, I believe that every knife tells a story—a story of its maker, its purpose, and the traditions it upholds. Whether you prefer the elegance of Japanese knives or the resilience of Western knives, let us cherish the skills and dedication that go into creating these indispensable culinary companions.

Would you like to experience the sharpness of handcrafted knives from Sakai City, used by 98% of Japanese chefs?

Through our exclusive partnership with Shiroyama Knife Workshop, we bring you top-quality knives. In addition, we offer free Honbazuke sharpening, a protective Saya, and paid after-sales services to ensure long-term confidence.

KIREAJI's Three Promises to You

-

1. Exceptional Japanese Knives

Our knives, crafted by Sakai City's master artisans, combine traditional techniques with carefully selected materials, delivering unrivaled sharpness and durability.

-

2. For a Lifetime of Use

At KIREAJI, we see knives as lifelong companions. Each knife comes with a free saya, and we offer Honbazuke hand-sharpening by Shiroyama Knife Workshop in Sakai City.

-

3. Supporting the Joy of Continued Use

KIREAJI knives are made to grow with you. That’s why we provide trusted after-sales care (fee-based) .