Japanese Knife Structure

-

Why Can a Single Knife Transform Your Culinary Journey?

Have you ever thought of a knife as simply "a tool for cutting ingredients"?

Why are chefs around the world continuously fascinated by Japanese knives? Why are Japanese-made knives treated like treasures in the kitchens of Michelin-starred restaurants? The answer lies hidden in the "structure" of the knife.

-

A Knife is Your "Second Hand"

An exceptional knife feels like an extension of your own hand. It slices through tomato skin without breaking it, beautifully cuts delicate fish fillets, and julienne vegetables without crushing their cells. These techniques are made possible by the precise structural design of the knife.

In Japan, for approximately 1,000 years since the Heian period, craftsmen who inherited the techniques of sword smiths have been evolving knives for the art of cooking. Meanwhile, in the West, a knife culture developed that emphasized practicality and efficiency.

-

What You'll Discover on This Page

Why Understanding Structure Matters:

- You'll be able to choose the optimal knife for your cooking style

- You'll understand how to maximize your knife's performance

- Your cooking precision and enjoyment will improve dramatically

- Your understanding of ingredients will deepen, enabling more delicate cooking techniques

-

What You'll Learn:

- The fundamental differences between single-bevel and double-bevel edges and the secrets behind their magical sharpness

- The amazing manufacturing techniques of Japanese craftsmanship: "Awasemono" and "Honyaki"

- The science behind how knife structure creates sharpness and affects ingredients

- The differences in design philosophy between Japanese and Western knives

-

Your Culinary Passion Reaches a New Stage

Understanding knife structure is not merely about acquiring knowledge. It's about respect for ingredients, passion for cooking, and taking the first step toward improving your own skills.

Would you like to step into the world of "the perfect cut" that the world's finest chefs continue to pursue?

1. Is Your Knife a "Versatile Partner" or a "Specialized Craftsman"?

-

Pick up the knife in your kitchen. Is it a "reliable all-rounder" that can handle various ingredients with a single blade? Or is it a "specialized expert" designed for specific tasks?

This difference reveals the fundamental design philosophy gap between Japanese and Western knives.

-

-

Japanese Knives: The Craftsman's World of "Pursuing One Perfect Thing"

What Japanese Knives Aimed to Achieve

Japanese knives inherited Japanese sword techniques and evolved specifically for fish and vegetable preparation. Since Japanese cuisine values not crushing food cells and creating beautiful cross-sections, knives required ultimate sharpness and delicacy.

-

Characteristics of Japanese Knives:

- Single-edged structure: Good separation from ingredients, achieving beautiful cuts

- Specialized focus: Evolved for specific purposes like yanagiba (for sashimi), deba (for fish), and usuba (for vegetables)

- Ultimate sharpness: Razor-sharp edge that doesn't crush food cells

- Insert-style handle: Sustainable design where handles can be replaced when they rot

-

The Aesthetic of "Sharpening Culture"

Japanese people have a culture of "treasuring knives like swords". They regularly sharpen them to maintain their edge and use a single knife for decades. This transcends mere attachment to tools—it's a uniquely Japanese aesthetic.

-

Japanese Cuisine Approach: "Respect for Ingredients and Pursuit of Beauty"

- Cooking as art: Maximizing the beauty and flavor inherent in ingredients

- Ingredients as protagonist: Especially in sashimi, where knife sharpness affects taste

- Delicate technique: Precise cutting that doesn't crush food cells

-

Western Knives: Universal Practicality Born from the "Pursuit of Efficiency"

What Western Knives Aimed to Achieve

Western knives, introduced to Japan from the West after the Meiji period, developed against the backdrop of a meat-eating culture. Since Western cuisine involves boldly cutting meat with bones and preparing meat dynamically in stewed dishes, knives needed durability and versatility.

-

Characteristics of Western Knives:

- Double-edged structure: Symmetrical design that's easy for anyone to handle

- One knife, multiple roles: Versatility to handle meat, fish, and vegetables with a single blade

- Robust construction: Strength and durability to cut through bone-in meat

- Handle structure: Sturdy construction with the blade's core material sandwiched in the handle and secured with rivets

-

"Practicality-First" Rational Design

Historically, Western knife culture has emphasized "efficiency and practicality". When blades deteriorated, the tendency was to choose replacement with new tools rather than resharpening. This was a rational decision prioritizing time efficiency, not a disregard for quality.

-

Western Cuisine Approach: "Efficient Nutritional Intake"

- Cooking as means: Quickly and efficiently creating nutritious meals

- Completion through seasoning: Final flavor adjustment with sauces and spices

- Powerful cooking: Practicality to boldly process even bone-in meat

-

Fundamental Differences in Culinary Philosophy

The contrast between these two approaches reveals not just different tools, but entirely different relationships with food and cooking.

-

Modern Impact: Fusion and Evolution

Interestingly, the santoku knife most commonly used in Japanese homes today is actually a type of Western knife. This is a uniquely Japanese evolution born from fusing the gyuto (chef's knife) with Japanese knife techniques.

There are also double-edged Japanese knives (like nakiri knives) and Japanese-made Western knives (Japanese santoku, Japanese gyuto, Japanese petty knives), making the boundaries complex and intertwined.

-

The Worldview Embedded in a Single Knife

When you hold a Japanese knife, you're gripping the "crystallization of a thousand years of craftsmanship and aesthetic sense". It's an artwork that embodies respect for ingredients and the aspiration for the perfect cut.

When you hold a Western knife, you're gripping an "efficient and practical universal tool". It's a reliable partner perfectly adapted to modern lifestyles.

-

What's Your Cooking Style?

- Pursuing ingredient beauty and caring about sharpness → Japanese knife specialization

- Time-saving, efficiency-focused, wanting one knife to handle everything → Western knife versatility

- Wanting both benefits → Japanese-made Western knives as an option

-

In the next section, we'll examine in detail how this philosophical difference manifests in "blade structure". The difference between single-edge and double-edge isn't merely a shape difference—it's the difference in approach to cooking itself.

2. The Art of Eastern and Western Blades: Japanese Single-Edge Knives vs. Western Double-Edge Knives - Philosophy and Practicality

-

In kitchens around the world, there exist two fundamentally different design philosophies in knife construction. The single-edge (kataba)knives born in Japan and the double-edge (ryoba)knives developed in the West - these differences represent more than mere shape variations; they embody the deep philosophies born from respective food cultures and craftsmanship traditions.

-

Single-Edge Knives: The Precision World Created by Japanese Craftsmanship

-

Traditional Japanese knives possess a beauty reminiscent of samurai swords. As the name suggests, only one side of the blade is sharpened, with the cutting edge extending from an area called the "Shinogi Suji" to the tip, defining the knife's cutting surface.

The Intricate Structure of Single-Edge Knives

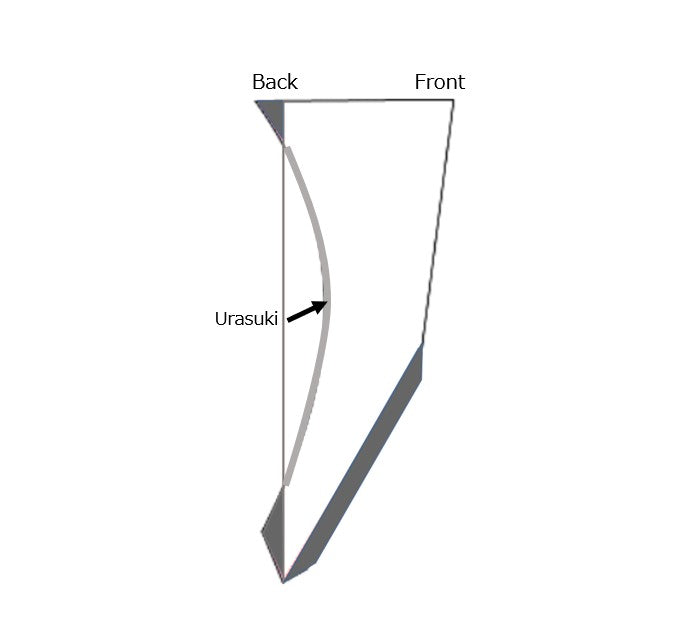

The most distinctive feature of single-edge knives lies in their asymmetrical design. While the front side (right side for right-handed users) is sharpened at an acute angle, the back side isn't completely flat. In fact, it features a subtle concave area called "urasuki," and this precise processing determines the performance of single-edge knives.

Due to this urasuki, the thinnest point is located on the back side, and since only one side contributes to the blade thickness, an exceptionally thin and sharp cutting edge is achieved. Even more fascinating is that during cutting, a natural gap forms between the food and blade, creating a unique effect that allows food to separate easily from the knife.

-

Advantages and Characteristics of Single-Edge Knives

Superior Sharpness

- Minimal resistance against food due to the ultra-thin blade edge

- Achieves beautiful cross-sections in sashimi and thinly sliced vegetables without crushing fibers

Ease of Sharpening

- Only one side needs sharpening, making maintenance relatively simple

- Easier to maintain consistent sharpening angles

High Specialization

- Purpose-specific designs: Deba knives (fish butchering), Yanagiba knives (sashimi), Usuba knives (vegetables)

-

Challenges of Single-Edge Knives

Technical Skill Requirements

Due to their asymmetrical design, single-edge knives require specific techniques and experience to master. Particularly for straight cuts, understanding the blade's characteristics is essential.Left-Handed User Considerations

Traditional single-edge knives are designed for right-handed users, so left-handed individuals need specialized left-handed knives. -

Double-Edge Knives: Western Rationality Pursuing Practicality

-

Western-developed double-edge knives feature symmetrical sharpening on both sides, emphasizing practical design. Santoku and Gyuto knives, widely used in Japanese households, belong to this category.

Structure and Design Philosophy of Double-Edge Knives

Double-edge knives literally have blades on both sides, maintaining asymmetrical shapearound the center line. This design allows intuitive blade insertion even into hard foods and provides versatility for various cutting tasks.

-

Advantages of Double-Edge Knives

- Capability with Hard Foods

Even force distribution from both sides enables stable cutting of hard root vegetables and meats. Hard vegetables like pumpkins and potatoes can be cut with ease due to the force-friendly design. - Ambidextrous Compatibility

The symmetrical blade shape allows both left and right-handed users to operate the knife equally well. This versatility is a significant advantage in today's diverse kitchen environments. - Multi-Purpose Functionality

One knife can process meat, fish, and vegetables, offering efficiency suited to modern busy lifestyles.

- Capability with Hard Foods

-

Limitations of Double-Edge Knives

- Thin-Slicing Constraints

Having blades on both sides makes it difficult to achieve cuts as thin as single-edge knives. They're particularly unsuitable for extremely thin slices like sashimi. - Sharpening Complexity

Maintaining balance between left and right sides during sharpening requires advanced technique. Equal adjustment of angles and pressure on both sides demands considerable skill.

- Thin-Slicing Constraints

-

Cultural Differences in Cutting Philosophy and Culinary Arts

-

The Aesthetics of "Hiki-giri" (Pull-Cutting) in Japanese Cuisine

Japanese cuisine places paramount importance on "bringing out the beauty of ingredients."Particularly in sushi and sashimi preparation, the "hiki-giri" technique using yanagiba knives creates mirror-like beautiful cross-sections without crushing fish fibers. This technique maximizes the fish's natural sweetness and texture.

-

The Pursuit of "Efficiency" in Western Cuisine

In contrast, Western cuisine emphasizes"efficient cooking processes."The requirement is to quickly process various ingredients with one knife and reduce cooking time. The versatility of double-edge knives perfectly meets this demand.

-

Optimal Choices in Modern Global Kitchens

-

Task-Specific Usage Strategies

Special Occasion Cooking - Single-Edge Knives Shine

- Sashimi and thin preparations where visual beauty is crucial

- Delicate vegetable decorative cuts and trimming work

- Fish filleting and other specialized technical tasks

-

Daily Cooking - Double-Edge Knives Excel

- Efficient daily meal preparation and prep work

- Processing various ingredients with one knife

- Tasks suitable for all skill levels from beginners to experts

-

Selection Guidelines Based on Skill Level

For Beginners

We recommend starting with user-friendly double-edge knives (Santoku knives). After mastering basic knife techniques, consider introducing single-edge knives when interest in specific cuisines develops.For Intermediate and Advanced Users

Using multiple knives for different purposes can dramatically improve cooking quality. Those interested in Japanese cuisine should consider introducing yanagiba or deba knives. -

The Future and Heritage of Knife Culture

-

These knives are not mere cooking tools but expressions of "deep love and respect for food" nurtured by their respective cultures. Japanese single-edge knives are artistic masterpieces infused with craftsmen's souls, while Western double-edge knives are engineering crystals pursuing rationality and practicality.

In today's globalized kitchens, understanding this East-West wisdom and using appropriate tools for specific tasks creates the ultimate cooking experience. Consider choosing the optimal companion knife based on your culinary passion and skill level - it will surely make your cooking world richer and more profound.

The choice between single-edge and double-edge knives ultimately reflects your cooking philosophy: the pursuit of perfection and artistry versus efficiency and versatility. Both approaches have their place in the modern kitchen, and the wisest cooks learn to appreciate and utilize both traditions.

3. The Mystical Technology of Japanese Knives: Three Precision Structures That Captivate the World and the Depths of Japanese Culinary Culture

-

Japanese knives are coveted by chefs worldwide. Behind their exceptional sharpness lie three precision technologies refined over centuries. These wa-bocho (Japanese knives), which transcend mere cooking tools to become works of art, capture the hearts of culinary professionals around the globe. But what makes them so captivating?

-

The Special Technology of Japanese Knives: Three Innovations Born from Craftsman's Wisdom

-

The phenomenal performance of Japanese single-edge knives is achieved through three precision technologies: tapering,angle variation (twist), and urasuki (back hollowing). These form a sophisticated system where each element works in harmony with the others, creating effects impossible to achieve individually.

-

The Precision Structure of Single-Edge Knives: Fusion of Science and Art

-

1. Tapering: Mastering Friction Through Minute Thickness Changes

The Miracle of Tapering

Japanese knife blades feature a "tapering" structure that gradually thins from heel to tip. This subtle thickness variation creates microscopic gaps between the food and blade during cutting, dramatically reducing friction.

- Smooth Cutting Sensation: Both push-cuts and pull-cuts can be performed without resistance

- Food Protection: Preserves the original texture of ingredients without crushing fibers

- Freshness Preservation: Prevents deterioration from frictional heat, maintaining ingredient beauty on the plate

-

tapering

Exquisite Balance Through Craftsmanship

Adjusting this tapering relies on the delicate sensibilities of skilled bladesmiths. Excessive tapering compromises durability, while insufficient tapering reduces sharpness. This exquisite balance represents the essence of Japanese knives.

-

2. Angle Variation (Twist): Calculated Angle Design

The Secret of Angles

Japanese knife edges feature subtle angle changes from heel to tip. This "twist" technology achieves optimal sharpness for specific applications.

-

Specific Angle Design Examples:

- Yanagiba Knife: Heel 13° → Tip 11° (achieving beautiful sashimi cuts)

- Usuba Knife: Heel 10° → Tip 8° (handling delicate vegetable cutting)

-

The Importance of Sharpening

Maintaining these angle variations is essential for preserving knife performance. Without proper sharpening techniques, this precision design loses its meaning.

-

3. Urasuki: The Greatest Innovation of Japanese Knives

Concave Structure Creating Phenomenal Sharpness

The "urasuki" concave structure applied to the back surface of single-edge knives is truly the hallmark technology of Japanese knives. This design minimizes contact area with food, achieving ultimate sharpness.

-

Effects of Urasuki:

- Friction Minimization: Extremely small contact area enables smooth cutting

- Flavor Protection: Particularly vital for sashimi, preserving the delicate umami of fish

- Point Contact Achievement: Ideal cutting state where only one point of the blade touches the ingredient

-

urasuki

Precision Processing Technology

Creating proper urasuki requires advanced technique and experience. Too wide compromises strength, too narrow reduces effectiveness, demanding exceptional craftsman skill.

-

Why These Technologies Emerged: Deep Connection with Japanese Culinary Culture

-

Supreme Respect for Ingredients

The fundamental philosophy of Japanese cuisine—"maximizing the beauty of ingredients"—gave birth to these precision technologies. Fresh fish sashimi, seasonal vegetable thin slices—in these dishes, the beauty of the cut surface itself becomes part of the flavor.

-

Fusion of "Ma" Aesthetics with Technology

The uniquely Japanese concept of "ma" (negative space) is reflected in knife technology. The microscopic space between ingredient and blade, the rhythm created by angle changes, the point contact from urasuki—all of these form the technological foundation supporting Japanese cuisine's delicacy.

-

Adaptation to Seasonal Ingredients

To handle the diverse ingredients nurtured by Japan's rich four seasons, knives also diversified. Spring bamboo shoots, summer sea eel, autumn saury, winter pufferfish—knife design philosophy optimized for each ingredient developed these precision technologies.

-

Inheritance of Craftsman Culture

Japan's craftsman culture tradition of "skill inheritance" has continuously refined these technologies across generations. The accumulation of minute techniques passed from master to apprentice has created today's sophisticated Japanese knives.

-

Universal Appeal to the World

-

Today, chefs specializing in French and Italian cuisine are also captivated by Japanese knives. This is because the sharpness created by these technologies holds universal value transcending culinary genres.

Respect for ingredients, pursuit of technical excellence, quest for beauty—these are universal values shared by chefs worldwide. Japanese knife precision technology serves as the ultimate tool for materializing these culinary aspirations, continuing to be beloved across borders.

Chefs around the world, please try holding a Japanese knife at least once. Its phenomenal sharpness will surely bring a new dimension to your cooking. Together with the Japanese spirit embedded in the technology, why not expand the possibilities of your cuisine?

The three precision structures of Japanese knives—tapering, twist, and urasuki—represent more than technical achievements. They embody centuries of cultural refinement and the relentless pursuit of culinary perfection that defines Japanese craftsmanship. In a world where cuisine knows no borders, these tools serve as bridges connecting different culinary traditions through their universal language of exceptional performance.

4. Understanding Japanese Knife Culture: The World of Craftsmanship Through Manufacturing Methods and History

-

-

Manufacturing Method Differences: Diversity Born from Tradition

Japanese knives possess vastly different characteristics depending on their manufacturing methods. This is not merely a difference in tools, but the crystallization of wisdom born from Japan's artisan culture and deep understanding of cuisine. For culinary enthusiasts overseas, understanding these differences is a crucial key to appreciating the delicacy and precision of Japanese cuisine.

-

Japanese-Style Knives: Honyaki vs. Kasumi (Awase)

Honyaki: Pure Steel Artistry

Honyaki knives truly deserve to be called "steel artistry." Created through forging from a single piece of steel, these knives are born through traditional techniques that inherit Japanese sword-making technology. Their hardness and sharpness are unmatched, achieving the precision and durability that professional chefs demand.

However, this superior performance comes with trade-offs. Due to their high hardness, sharpening requires advanced techniques, and proper whetstone selection is crucial. There's also risk of chipping or breaking due to brittleness, requiring careful handling. Furthermore, due to the complexity of the manufacturing process, quality is heavily dependent on the craftsman's skill.

-

Kasumi (Awase): Harmony of Practicality and Beauty

Kasumi knives perfectly balance ease of use and aesthetic appeal. By combining a steel core with soft iron, they achieve sharpening ease and handling convenience, making them suitable for users from beginners to professionals. Their affordability compared to Honyaki knives is also a major attraction.

However, the combination of materials with different hardness and elasticity may cause warping or distortion over time. Additionally, improper bonding during manufacturing can lead to performance degradation, making skilled craftsmanship essential.

-

Western-Style Knives: Zenkou (All Steel) vs. Kasumi Hari Awase

Zenkou (All Steel): Monolithic Strength

All-steel knives are robust knives made from a single piece of hard steel. Since the entire blade is composed of hard material, they resist chipping and maintain sharp cutting performance for extended periods. They can accommodate single-edge sharpening and are suitable for professional delicate work.

However, due to the hard steel material, sharpening requires technique and time, and the absence of soft supporting layers makes them vulnerable to impact. Additionally, using high-quality materials throughout tends to increase costs.

-

Kasumi Hari Awase: Wisdom of Multi-Layer Construction

These are multi-layer knives made by combining multiple metals, typically featuring a three-layer structure with hard steel sandwiched between soft metals. The soft outer layers absorb impact, improving overall durability. They excel in ease of sharpening and cost-performance, with designs that are beginner-friendly.

However, soft outer layers are prone to deformation under pressure, potentially affecting the core material. Compared to all-steel knives, edge retention is somewhat inferior, and the two-layer structure is not suitable for single-edge sharpening.

FAQ About Single-Edged and Double-Edged Knives

What's the difference between single-edged and double-edged knives?

Single-edged knives have a blade on only one side, with the other side being flat or slightly concave. This is a characteristic feature mainly found in Japanese wa-bocho knives, enabling precise cutting. On the other hand,double-edged knives have blades on both sides, a design commonly seen in Western and Chinese knives that offers excellent versatility.

Why did single-edged knives develop in Japan?

This was the result of pursuing the delicacy and precision of Japanese cuisine. They were particularly developed for fish preparation, creating beautiful cut surfaces without damaging the ingredient's structure. The influence of Japan's sword-making technology also played a significant role.

Which should beginners choose?

We recommend double-edged knives for beginners. Here's why:

- Easier to sharpen

- More user-friendly

- Suitable for diverse cuisines

- Relatively affordable

- Can be used by both left and right-handed users

Do cutting techniques differ between single-edged and double-edged knives?

Yes, there are significant differences in cutting techniques:

Single-edged knives:

- Pull-cutting is fundamental

- Hold the blade perpendicular to the ingredient

- Complete the cut in one motion

- Cut without crushing the ingredient's fibers

Double-edged knives:

- Both push-cutting and pull-cutting are possible

- Cut while moving back and forth

- Accommodate more diverse cutting techniques

Can left-handed people use single-edged knives?

Left-handed specific single-edged knives exist. Regular single-edged knives are designed for right-handed users, so left-handed people would find the blade pulling away from ingredients, making proper cutting difficult. Left-handed versions have the blade orientation reversed.

Why Are Japanese Knives Single-Edged?

-

Japanese culinary knives, or wa-bocho, are renowned not only for their razor-sharp edges but also for a unique design trait that sets them apart from most Western and Chinese knives—the single-edged blade.

At first glance, this might seem like a stylistic or cultural quirk. But in fact, it reflects a deeply practical and philosophical approach to cooking, rooted in Japan’s long history of craftsmanship and respect for ingredients. Here’s why this design came to be—and why it still matters.

-

1. Functional Precision: A Tool Designed for Purity

The single-edge design is no accident; it was born out of necessity—especially in the preparation of fish, a cornerstone of Japanese cuisine. With a single bevel, chefs can make incredibly precise cuts that separate flesh from bone cleanly, without tearing the meat or clouding the broth with unwanted fragments.

The result is more than just clean fillets—it’s about preserving texture, appearance, and flavor. In dishes like sashimi or kaiseki, where presentation and ingredient integrity are paramount, this precision makes all the difference.

-

2. A Product of Historical Refinement

The roots of the modern Japanese kitchen knife stretch back to the Genroku period (1688–1704), when swordsmiths, no longer needed for warfare in a time of peace, turned their attention to cutlery. Records suggest that specialized kitchen knives emerged during this era, developed to meet the needs of elite chefs preparing meals for the imperial court and the nobility.

This shift from battlefield to kitchen was not just a change of profession—it marked the beginning of a new craft, where the same reverence for steel and skill was applied to the art of food.

-

3. Edo Period: When Peace Nurtured Precision

During the Edo period (1603–1868), Japan enjoyed over two centuries of relative peace and isolation. Without wars to fight, artisans, chefs, and craftspeople refined their trades. Culinary arts flourished, and with them, tools like the yanagiba and deba were developed to handle the delicate demands of Japanese cuisine.

In this environment, the single-edged blade wasn’t just maintained—it was perfected.

-

-

4. Inheritance of Sword Culture

Japan’s expertise in blade-making is legendary, with techniques honed through centuries of swordsmithing. That same philosophy—of balancing hardness, sharpness, and beauty—was eventually passed down to kitchen knives.

A famous anecdote tells of Emperor Go-Toba, who not only supported swordsmiths but took part in forging swords himself. This reverence for bladed tools embedded a deep cultural pride in craftsmanship, which lives on in the kitchen knife.

-

5. The Urasuki: Hidden Geometry, Maximum Control

One of the most ingenious features of Japanese single-edged knives is the urasuki, a slight concave on the blade’s back side. This subtle hollow reduces friction and prevents food from sticking to the blade. It’s a detail rarely found outside of Japan and is difficult to produce without great skill.

The urasuki doesn’t just make slicing smoother—it’s a quiet reminder that even the unseen parts of a tool deserve attention and care.

-

6. Tangible History: Evidence in Steel

Historical blades from the 17th century show clear signs of laminated construction and a single bevel. These early examples prove that the core concepts of today’s wa-bocho were already in place over 400 years ago—unchanged not because of stagnation, but because they were already near perfection.

-

Form, Function, and Philosophy

In the end, the single-edged design of Japanese knives is not just a matter of function—it’s a reflection of cultural values. It embodies a relentless pursuit of precision, a deep respect for ingredients, and a quiet, humble beauty that rewards those who take the time to understand it.

To hold a wa-bocho is to hold a piece of living history—one that continues to evolve, cut by cut, meal by meal.

The Difference Between Honyaki and Zenkou (All Steel) Knives

-

-

Knives made from a single piece of hard steel come in two distinct types: Honyaki and Zenkou (All Steel). Understanding these differences is crucial when choosing a knife.

-

Firstly, Honyaki refers to knives created through forging, a meticulous process where steel is repeatedly hammered and shaped. This method is reminiscent of traditional Japanese sword-making, where artisans use their skill to craft each knife by hand. Forging involves heating the metal and shaping it with a hammer, aligning the internal crystal structure and compressing it. This process imparts exceptional durability and toughness to the blade, which is crucial for withstanding impact and stress. A Honyaki knife, forged in this manner, boasts remarkable hardness and sharpness, even allowing thin blades to cut through food effortlessly. Its precision ensures that the edge remains sharp for an extended period, minimizing the need for frequent sharpening. This is the essence of craftsmanship in Honyaki knives.

-

A Honyaki knife is not just a tool but a piece of artistry imbued with the skill and passion of the craftsman. The sensation of the blade gliding through ingredients, the beauty of the precise cuts, and the lasting sharpness offer an unparalleled experience. For those who value the art of cooking, a Honyaki knife elevates both the preparation and presentation of food, making it a prized choice for professionals and enthusiasts alike.

-

In contrast, Zenkou (All Steel) knives are made from a single piece of steel that is simply shaped using a mold. These knives lack the forging process, which results in a less refined internal structure, leading to lower durability and toughness compared to Honyaki knives. However, Zenkou (All Steel) knives are cost-effective and suitable for everyday use.

-

Honyaki knives, with their special technique and craftsmanship, offer unmatched beauty and performance. For those seeking a superior knife, Honyaki provides an exceptional option that stands out from the rest.

The Origin of Craftsmanship

-

The Art of Japanese and Western Knives: A Craftsman's Perspective

In the world of knives, the differences betweenJapanese knives (Wabōchō)andWestern knives (Yōbōchō)are more profound than they may appear at first glance. As a traditional craftsman, I’d like to share insights into what makes Japanese knives exceptional, while also acknowledging the unique traits of their Western counterparts.

-

The Elegance of Japanese Knives

Japanese knives are renowned for their precision and artistry. One of their defining characteristics is the tapered design, or "teppā", which creates a gradual reduction in thickness from the spine to the edge. This meticulous craftsmanship not only contributes to the knife’s sharpness but also ensures minimal resistance when slicing through ingredients.

Additionally, Japanese knives often feature a single-beveled edge, which provides unparalleled control and accuracy. This design, combined with a hollow grind on the reverse side (Urasuki), minimizes the surface area that comes into contact with the food. As a result, flavors remain intact, textures stay true, and each slice becomes a culinary experience.

-

The Versatility of Western Knives

On the other hand, Western knives are celebrated for their durability and versatility. With theirdouble-beveled edges, they accommodate a broader range of tasks and are generally easier for beginners to handle. While they might not match the intricate precision of Japanese knives, they are indispensable for heavy-duty tasks such as cutting through bones or dense vegetables.

-

Why Choose Japanese Knives?

The secret of Japanese knives lies in their ability to enhance the natural flavors of the ingredients. By reducing friction and maintaining a razor-thin edge, they prevent unnecessary damage to delicate fibers, ensuring that every cut delivers the purest taste. For example:

- Sashimi, prepared with a Yanagiba knife, retains its smooth, pristine surface and fresh taste.

- Vegetables sliced with a Nakiri knife exhibit clean, unblemished edges, which preserve their moisture and crispness.

-

Challenges of Mastering Japanese Knives

However, crafting and maintaining Japanese knives is no simple feat. The meticulous processes, from forging to sharpening, require a deep understanding of metallurgy and geometry. For users, sharpening Japanese knives demands attention to edge angles, as improper techniques can compromise their performance.

Yet, for those willing to embrace the challenge, the rewards are unmatched. Japanese knives aren’t just tools—they are extensions of the chef’s hand, bridging the gap between tradition and innovation.

-

Appreciating Both Worlds

While Japanese knives excel in precision and artistry, Western knives provide strength and adaptability. Rather than viewing them as competitors, we should celebrate their unique strengths and recognize how they complement different cooking styles.

By understanding the philosophy behind their design, one can fully appreciate the culinary heritage and craftsmanship that each type represents. After all, the knife you choose is not just a reflection of your cooking needs but also a testament to your respect for the ingredients and the art of cuisine.

-

As a craftsman, I believe that every knife tells a story—a story of its maker, its purpose, and the traditions it upholds. Whether you prefer the elegance of Japanese knives or the resilience of Western knives, let us cherish the skills and dedication that go into creating these indispensable culinary companions.

Would you like to experience the sharpness of handcrafted knives from Sakai City, used by 98% of Japanese chefs?

Through our exclusive partnership with Shiroyama Knife Workshop, we bring you top-quality knives. In addition, we offer free Honbazuke sharpening, a protective Saya, and paid after-sales services to ensure long-term confidence.

KIREAJI's Three Promises to You

-

1. Exceptional Japanese Knives

Our knives, crafted by Sakai City's master artisans, combine traditional techniques with carefully selected materials, delivering unrivaled sharpness and durability.

-

2. For a Lifetime of Use

At KIREAJI, we see knives as lifelong companions. Each knife comes with a free saya, and we offer Honbazuke hand-sharpening by Shiroyama Knife Workshop in Sakai City.

-

3. Supporting the Joy of Continued Use

KIREAJI knives are made to grow with you. That’s why we provide trusted after-sales care (fee-based) .