-

Japanese Knife Materials

-

By introducing the materials used in knives, we aim to help customers understand the quality and performance of knives, enabling them to find the perfect knife that meets their needs and preferences.

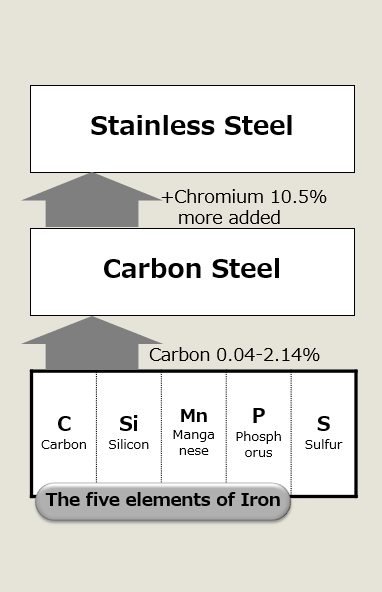

Iron, in its raw state, is riddled with impurities, making it prone to rust and brittleness—less than ideal for kitchen knives. By removing these impurities and adding carbon, iron is transformed into carbon steel, enhancing its hardness and durability for culinary use.

Carbon Steel:

Characterized by a carbon content of 0.04-2.14%, this material strikes a balance between hardness and edge retention, making it a popular choice for many kitchen knives.

Stainless Steel:

The game changes when over 10.5% chromium is introduced to carbon steel, evolving it into stainless steel, celebrated for its exceptional resistance to rust. This meticulous alloying process crafts knives that are not just high-performing but also durable, able to withstand the rigors of kitchen life.

Discovering the Science Behind Japanese Knives

-

Japanese knives, with a rich history of over 600 years, trace their roots back to the Azuchi-Momoyama period. These knives are celebrated not only for their exquisite craftsmanship but also for their remarkable functionality. Today, advancements in science have taken this traditional craft to molecular levels, offering a deeper understanding of their superior performance.

-

Imagine driving a car daily but not fully grasping how its engine powers motion or its brakes bring you to a halt. This is the case for many professional chefs as well—they wield Japanese knives daily but might not fully comprehend why these blades cut so effortlessly, resist corrosion, or chip under certain conditions.

-

By understanding the science behind knife materials, you can go beyond appreciating their beauty and sharpness. You’ll be able to select a knife tailored to your needs and master its use, unlocking its full potential. Here, we’ll explore two key factors: carbon content and alloy composition, which significantly influence a knife’s performance.

-

1. The Role of Carbon: A Sharp Edge and Beyond

Carbon is the heart of steel. Though it constitutes a mere 1% of the material, even a 0.1% difference can create a noticeable variation in sharpness and hardness. Higher carbon content increases the blade's hardness, resulting in superior sharpness and edge retention. However, it also requires more maintenance, as these blades are prone to chipping and demand skillful sharpening.

-

For instance:

- White Steel (Shirogami) is revered for its unparalleled sharpness but requires meticulous care.

- Blue Steel (Aogami) incorporates elements like tungsten and chromium, enhancing its toughness and rust resistance, making it easier to handle without sacrificing performance.

-

2. Alloy Composition: The Key to Craftsmanship

Steel isn't just about carbon. The additional elements in the alloy, such as chromium, tungsten, or vanadium, significantly affect the knife’s properties and its crafting process. Each type of steel demands precise temperature control during heat treatment, a process known as "quenching."

-

The legendary White Steel knives, especially pure "water-quenched" varieties, require such strict heat management that even master craftsmen risk cracking the blade during cooling. On the other hand, Blue Steel, with its added elements, offers a more forgiving tempering process while still achieving exceptional sharpness and durability.

-

This intricate balance between heat treatment, composition, and craftsmanship explains why Japanese knives are often likened to samurai swords—both require meticulous quenching to unlock their full potential.

-

-

Empower Your Choice with Knowledge

Understanding these scientific aspects of Japanese knives allows you to make informed choices. Are you looking for a knife with razor-sharp precision, or do you prioritize durability for daily kitchen tasks? By considering carbon content and alloy composition, you can select the perfect blade that resonates with your cooking style.

-

Owning a Japanese knife isn’t just about having a tool; it’s about embracing a centuries-old tradition refined by modern science. With proper care and understanding, your knife will become an extension of your craft, making every slice, chop, and cut a seamless experience.

-

Why Carbon Steel Knives Cut Better Than Cheap Stainless Steel Knives

-

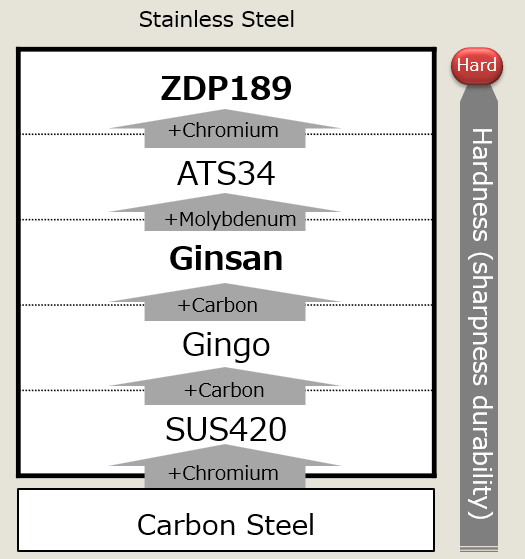

It is often said that carbon steel knives cut better than stainless steel knives. However, not all stainless steel knives are inferior. In fact, high-end stainless steels such as Super Steel, ZDP189, and Ginsan (Silver #3 Steel) can achieve cutting performance equivalent to carbon steel when properly heat-treated and sharpened.

-

That being said, many cheap stainless steel knives, commonly found in supermarkets, are made from low-hardness stainless steel to reduce costs. These knives often lack the sharpness and edge retention of carbon steel knives. Let's explore why carbon steel knives outperform these budget-friendly stainless steel alternatives.

-

1. Sharpness Depends on How Easily the Blade Can Be Sharpened

A knife’s cutting performance is not only determined by how sharp it is but also by how easily the edge can be maintained through sharpening.

-

Imagine making breadcrumbs. Would it be easier to grate a hard, crispy loaf of bread or a soft, chewy one? The hard bread crumbles easily, while the soft one resists and stretches. This same principle applies to sharpening carbon steel vs. cheap stainless steel knives.

-

- Carbon steel knives are made of iron with added carbon (C), allowing them to be hardened significantly through heat treatment. When sharpened, the metal breaks away cleanly in fine particles, making it easy to maintain a razor-sharp edge.

- Cheap stainless steel knives contain a high percentage of chromium (Cr) to enhance rust resistance. However, this reduces the carbon content, making the steel softer and more ductile. When sharpened, the metal stretches instead of breaking away cleanly, making it difficult to achieve a precise, razor-sharp edge.

-

2. Low-Hardness Stainless Steel Has Limitations

One of the most critical factors in knife performance is hardness, typically measured in HRC (Rockwell Hardness Scale). A harder steel can hold a sharp edge longer and resist dulling.

-

- Carbon steel knives can be hardened to HRC 60 or higher, allowing them to maintain an exceptionally sharp edge.

- Cheap stainless steel knives often have an HRC of 55 or lower, meaning the edge wears down quickly and requires frequent sharpening.

-

Additionally, many mass-produced stainless steel knives are not given a refined sharpening process, meaning that even out of the box, they do not cut as well as a properly sharpened carbon steel knife.

-

3. High-End Stainless Steel and Cheap Stainless Steel Are NOT the Same

It's important to understand that not all stainless steel knives are inferior to carbon steel knives.

-

- Premium stainless steels such as Super Steel, ZDP189, and Ginsan are engineered for high hardness and excellent edge retention. When heat-treated and sharpened correctly, they can perform just as well as carbon steel knives.

- However, cheap stainless steel knives, commonly found in supermarkets, are made with low-grade steel that lacks the necessary hardness for fine edge retention. These knives are designed for affordability rather than high performance, making them significantly weaker in cutting ability compared to carbon steel knives.

-

Conclusion: Carbon Steel Knives Offer Superior Sharpness and Durability

The reason carbon steel knives outperform cheap stainless steel knives is their higher hardness, easier sharpening, and superior edge retention.

-

While high-end stainless steel knives can match carbon steel in cutting performance, they are often expensive. On the other hand, cheap stainless steel knives, while affordable and rust-resistant, struggle to maintain a sharp edge and are far less effective than carbon steel knives.

Element

Carbon(C)

Carbon (C) is an essential element for steel, and it is a key element in creating various compounds and elements. It is a representative element for increasing hardness and strength.

Chromium(Cr)

Chromium (Cr) improves hardenability. Stainless steel contains 10.5% or more of Cr.

Manganese (Mn)

Manganese (Mn) is an element that makes quenching easier and increases toughness.

Molybdenum

Molybdenum is used to make V1 to V10. (It is originally contained in V1 as well.) Adding a small amount makes it more tenacious. It also increases strength and hardness. Molybdenum steel is often referred to as molybdenum steel, but molybdenum steel is a general term for steel materials that contain molybdenum. It is not the name of a specific steel material, such as white steel, but a steel material that contains molybdenum is widely referred to as "molybdenum steel.

Phosphorus (P)

Phosphorus (P) is a harmful element in steel, which causes cold brittleness, making steel brittle in cold conditions. Therefore, it is necessary to limit its content as much as possible.

Silicon(Si)

Silicon (Si) is an element that increases hardness and strength.

Sulfur(S)

Sulfur (S) is a harmful element for steel as it causes hot-shortness, meaning it makes the steel brittle when in a red-hot state. The content of sulfur should be as low as possible.

Tungsten(W)

Tungsten (W) is an element that improves heat treatment characteristics and increases hardenability. It also improves wear resistance.

1. Carbon Steel

-

When it comes to knives, the choice of steel significantly impacts sharpness, durability, and ease of maintenance. Among various materials, carbon steel stands out for its ability to achieve an exceptionally sharp edge. This is why many professional chefs and knife enthusiasts prefer carbon steel knives.

-

The Key Difference Between Carbon Steel and Stainless Steel

Both carbon steel and stainless steel contain more than 70% iron (Fe) as their primary component. However, iron naturally reacts with water and oxygen, leading to rust and corrosion over time. To prevent this, stainless steel contains at least 10.5% chromium (Cr), which enhances its resistance to rust.

-

However, simply adding chromium is not enough to ensure the necessary toughness, flexibility, and long-lasting sharpness required for a high-performance knife. This is why various alloying elements are added to stainless steel. Many of these additives make the steel more resistant to wear, which helps maintain sharpness over time. However, this also makes stainless steel knives more difficult to sharpen on a whetstone.

-

On the other hand, carbon steel contains fewer additives, making it easier to sharpen and allowing for a finer, sharper edge. For those who value ultimate sharpness and precision, carbon steel knives are an excellent choice, as long as proper maintenance is observed.

-

-

Yasuki Steel (Yasuki Hagane) – Japan’s Finest Carbon Steel

Among the many types of carbon steel, Yasuki Steel (Yasuki Hagane) is one of the most highly regarded. Manufactured by Hitachi Metals, Ltd. in Yasugi City, Tottori Prefecture, this high-quality steel is widely used for crafting knives, scissors, and agricultural tools.

-

For traditional Japanese knives, three main types of Yasugi Steel are used: "Yellow Paper Steel," "White Paper Steel," and "Blue Paper Steel." These names originate from the colored paper labels that Hitachi Metals used to identify each type of steel.

-

Knives made from Yasugi Steel offer sharper edges than stainless steel and are easier to sharpen. However, they require regular maintenance to prevent rust, and due to their high hardness, they are more prone to chipping.

-

For chefs who prioritize superior sharpness and don’t mind investing time in maintenance, Yasugi Steel knives are an excellent choice that delivers unparalleled cutting performance.

-

SK Steel:

- A common carbon steel used for tools like knives.

- Often found in affordable household knives.

- The carbon content is typically around 0.55% to 1.5%.

-

Yellow Steel (Kigami Steel):

- Based on SK steel, with around 50% high-purity iron sand added.

- It offers better quality than SK steel but still contains more impurities compred to white or blue steel.

- It is relatively affordable and easy to sharpen.

-

White Steel (Shirogami Steel):

- A highly pure steel made by further removing impurities from yellow steel.

- It is known for being easy to sharpen and having an exceptionally sharp edge.

- However, it is difficult to heat treat, requiring the skill of a master craftsman.

-

Blue Steel (Aogami Steel):

- is highly wear-resistant and retains its sharpness for a long time.

- While it is tougher and more resistant to chipping than white steel, it can be more difficult to sharpen.

-

Relationship:

As you progress fromSK steel → Yellow steel → White steel → Blue steel, thepurity, quality, and performanceimprove.

At the same time, theprice increases, and thedifficulty in handlingalso rises. Each type of steel is chosen based on its purpose and the user's skill level. -

Who Should Choose a Carbon Steel Knife?

1. Those Who Can Properly Maintain Their Knives

Carbon steel knives require careful handling to prevent rust. However, as long as you wipe off moisture and remove any rust that appears, they are easy to maintain. They are also easier to sharpen than high-end stainless steel knives and are often more affordable, making them a popular choice among professional chefs.

-

2. Those Who Use Their Knives for Extended Periods

For those working in food processing facilities or professional kitchens, carbon steel knives offer excellent cost-performance since they can be easily resharpened and maintained throughout the day.

※ However, some workplaces may prohibit carbon steel knives due to hygiene regulations, so it’s best to check before using them. -

3. Traditional Japanese Cuisine Chefs

Carbon steel knives are the standard in Japanese cuisine. Many chefs inherit knives from their mentors or colleagues, so it’s essential to become familiar with handling and maintaining carbon steel knives early on. While transitioning from carbon steel to stainless steel is relatively easy, moving from stainless steel to carbon steel can be challenging due to the increased risk of rust.

White Steel vs Blue Steel

-

White Steel (Carbon Steel): Choose for Ease of Sharpening

Features: White steel is favored for its ease of sharpening and excellent cutting performance. It can be sharpened to a sharp edge quickly, although the sharpness may decrease with frequent use. The quick resharpening process allows for easy maintenance of optimal sharpness.

-

Blue Steel (Alloy Steel ): Choose for Lasting Sharpness

Features: By adding chromium (Cr) and tungsten (W) to carbon steel, blue steel's sharpness durability significantly improves. It can maintain good sharpness with infrequent sharpening, even with high volume cutting. However, while blue steel maintains sharpness longer due to its components, it is harder to sharpen. Additionally, the enlargement of the metal's structure can slightly decrease sharpness.

-

Differences between Steel #1, Steel #2, and Steel #3

-

While knives have a silver appearance, when sharpened, the slurry produced turns black. This is because the slurry contains carbon, a key component that provides the knife with hardness.

-

The hardness of steel is classified as #1, #2, and #3, with lower numbers indicating greater hardness. For example, Steel #1 offers the highest level of hardness and provides the sharpest edge. Steel #2 and Steel #3 follow in order, with progressively lower hardness and sharpness, though they still maintain sufficient sharpness for most purposes.

-

It is often said that the more carbon steel contains, the better the sharpness. This is because the carbides formed in the steel provide more grip when cutting, which contributes to a sharper edge. Additionally, harder steel has better edge retention, allowing the blade to stay sharp for longer periods.

-

One of the advantages of harder steel is that it requires less force to cut. For example, when knives with different hardness levels are sharpened at the same angle and used with the same force, the harder steel will generally cut more effectively. However, as steel becomes harder, it also becomes more prone to chipping and is more difficult to sharpen.

-

Steel #1: Focused on Sharpness

#1 is recommended for knives that require exceptional sharpness, such as those used for slicing delicate dishes like fugu sashimi or thin slices of sea bream, due to its excellent cutting ability.

-

Steel #2: Focused on Balance

#2 offers a good balance between sharpness and ease of sharpening, making it suitable for cutting a variety of ingredients, from vegetables to meats.

-

Steel #3: Focused on Ease of Sharpening

#3 is easy to sharpen, making it ideal for knives that may chip, such as those used for filleting fish, since it can be quickly resharpened.

Features of Blue Steel #1

-

Extremely High Hardness and Sharpness

Blue Steel #1 is a material known for its high carbon content, which contributes to its exceptional hardness. When properly sharpened, it can achieve an impressively sharp edge.

-

Excellent Wear Resistance

Due to its high hardness, knives made from Blue Steel #1 maintain their sharpness for extended periods, holding their edge better compared to regular knives.

-

Challenging to Handle

Blue Steel #1 is extremely hard, which makes it difficult to sharpen and may not be suitable for beginners. Due to its hardness, the sharpening stone can slip, requiring a skilled technique to sharpen effectively.

Features of Blue Steel #2

-

Stable Sharpness

Blue Steel #2, known for its high carbon content, is extremely hard. This quality allows it to maintain a sharp edge for an extended period once sharpened.

-

Wear Resistance

Due to its high hardness, knives crafted from Blue Steel #2 retain their sharpness longer than regular knives, offering superior wear resistance.

-

Hard to Sharpen

Blue Steel #2 is hard, making it challenging to sharpen and requiring skilled maintenance or extra effort. Compared to Blue Steel #1, it has better abrasion resistance on sharpening stones, making sharpening easier.

Features of White Steel #1

-

Exceptional Sharpness and Hardness

With an increased carbon content, White Steel #1 achieves exceptional sharpness and boasts a high hardness rating of HRC66, making it an ideal material for Japanese knives, particularly those used in traditional cuisine.

-

Ease of Sharpening

Due to its low levels of additives and impurities, White Steel #1 is surprisingly easy to sharpen with a whetstone, a rare quality for such a high-hardness knife steel.

-

Pure Steel Composition

Free from tungsten (W) and chromium (Cr), which are commonly found in blue steel, White Steel #1 is praised for its purity and ease of maintenance, offering a balance between sharpness and usability despite being less wear-resistant than blue steel.

Features of White Steel #2

-

Sufficiently Sharp Edge

White Steel #2 is a material with a high carbon content, making it extremely hard. When sharpened, it exhibits a sharp edge.

-

Not Highly Difficult to Sharpen

White Steel #2 is not as hard as blue steel, so it is not highly difficult to sharpen. It can be considered relatively easy to handle even for beginners.

-

Good Cost Performance

White Steel #2 is not as expensive as the top-grade White Steel #1, making it a good choice in terms of cost performance.

Comprehensive Guide to White Steel and Blue Steel

When choosing a knife, the debate between blue steel and white steel resonates among chefs and culinary enthusiasts alike. Each type of steel offers unique advantages tailored to different cooking styles and maintenance preferences. This article explores the differences between blue and white steel, helping you make the best choice for your kitchen tools.

Comprehensive Guide to White Steel #2 and Blue Steel #2

Explore the essential differences between White Steel #2 and Blue Steel #2 in our guide, focusing on their cutting performance, durability, and ease of sharpening. This article provides practical insights for chefs and cooking enthusiasts to make an informed choice between these two popular steel types for kitchen knives.

Comprehensive Guide to Blue Steel #1 and Blue Steel #2

Explore the key differences between Blue Steel #1 and #2 knives, focusing on sharpness, durability, and user needs, to help you choose the right one for your cooking tasks.

Comprehensive Guide to White Steel #1 and White Steel #2

White Steel #1 and White Steel #2 are among the most popular materials used in Japanese knives. This guide compares their unique characteristics and performance to help you choose the best option for your cooking style and needs. Whether you’re a beginner or a professional chef, find valuable insights for selecting the perfect Japanese knife.

-

2. Stainless Steel

-

Stainless steel, true to its name, is highly resistant to rust and corrosion, making it a widely trusted material in kitchens and workshops around the world. One of its biggest advantages in knives is that it eliminates the need for rust maintenance, making it an ideal choice for both busy professionals and home cooks.

-

Who Should Choose Stainless Steel Knives?

1. If you are worried about rust maintenance

Traditional carbon steel knives require frequent maintenance, which can be a burden for home users. With stainless steel knives, you can simply wash them and let them dry naturally, making them much easier to handle in everyday cooking. -

2. If you don’t have time for rust care

In busy restaurant kitchens, especially in Japanese or sushi cuisine, chefs often don’t have time to wipe down their knives frequently. Stainless steel knives allow chefs to focus on their craft without worrying about rust. -

3. If you frequently cut foods that react with carbon steel

If you often cut fruits, a stainless steel petty knife is the best choice. Carbon steel knives are sensitive to acids, which can cause discoloration and faster rusting. For those handling acidic foods, stainless steel is the way to go. -

The Evolution of Stainless Steel and Expert Craftsmanship

The history of stainless steel began in 1904, when French scientist Léon Guillet discovered that adding 13% chromium to iron created a material that was far more resistant to rust. Then, in 1913, British scientist Harry Brearley revolutionized knife-making by inventing martensitic stainless steel, which combined chromium with carbon to create a hardenable, durable blade material.

-

Further improvements led to the development of molybdenum-vanadium steel, which increased toughness and minimized brittleness, making it a staple in premium-quality knives.

-

Today, stainless steel technology has advanced so much that its sharpness rivals that of carbon steel, while its durability and low maintenance make it a top choice for professionals and home cooks alike.

Additionally, as shown in the diagram on the left, these stainless steels are manufactured by Hitachi Metals, just like blue, white, and yellow steels. This highlights Japan’s cutting-edge metallurgy, which plays a crucial role in maintaining the high quality and diversity of Japanese knives.

-

ZDP189

ZDP189

Hitachi Metals' strongest powder steel, ZDP-189, boasts a hardness of 67 or higher, the highest of any known steel for cutting tools. It offers the ultimate combination of hardness, toughness, wear resistance, and corrosion resistance. However, due to its extreme hardness, ZDP-189 is difficult to sharpen with regular sharpening stones and is quiteexpensive.

-

Ginsan

Ginsan

Ginsan is a type of stainless steel known for its excellent balance between corrosion resistance and cutting performance. Manufactured by Hitachi Metals, this steel is widely recognized under the name "Ginsan." It features a high chromium content of 13-16%, which significantly enhances its resistance to corrosion. Additionally, the carbon content ranges from 0.8 to 1.3%, providing a good balance between hardness and toughness, ensuring stability during use.

Due to its superior sharpness and resistance to rust, Ginsan is extensively used in various types of blades, including kitchen knives. Trusted in both professional kitchens and homes, Ginsan steel makes daily culinary tasks more efficient and enjoyable.

-

Super Steel

-

In the world of traditional Japanese knives, steels like Ginsan and ZDP189 are widely known, but recently, the steel that has captured the attention of professional chefs worldwide is "Super Steel", proudly developed by Shiroyama Hamono Manufacturing.

-

This special semi-stainless steel contains rich amounts of molybdenum, chromium, and tungsten, offering high corrosion resistance, outstanding durability, and an excellent balance between sharpness retention and ease of sharpening. But the true allure of Super Steel lies not just in its technical properties—it is a fusion of traditional Japanese craftsmanship and cutting-edge technology, making it truly one-of-a-kind.

-

Craftsmanship in Every Step of Production

The unique qualities of Super Steel are unlocked through a meticulous production process. Two innovative techniques, vacuum heat treatment and sub-zero treatment, set this steel apart from any other.

-

Vacuum Heat Treatment:

By heating and rapidly cooling in a vacuum environment, this process prevents oxidation and results in uniform hardness and strength, ensuring that the knife maintains consistent sharpness over time and retains its form, no matter how long it's used.

-

Sub-Zero Treatment:

This treatment involves cooling the steel to sub-zero temperatures after heat treatment, enhancing hardness and improving dimensional stability. The result is a knife that performs excellently even under the most demanding conditions, meeting the exacting standards of professional chefs.

-

Performance That Professional Chefs Swear By

Knives made from Super Steel have earned high praise from chefs worldwide due to their exceptional sharpness and durability.

-

Incredible sharpness and longevity:

Achieving an impressive HRC 62±1 hardness, these knives retain their sharpness for an extended period, allowing for easy sharpening and use over the long term.

-

Outstanding corrosion resistance:

Super Steel is resistant to rust, making maintenance simple and ensuring the knife stays clean and hygienic even in the busiest kitchens.

-

Consistent quality:

By combining traditional craftsmanship with modern technology, Super Steel offers consistent high quality and reliability, making it a trusted tool in the hands of professional chefs.

-

A True Masterpiece of Japanese Tradition and Innovation

Super Steel is a perfect blend of Japan’s traditional blade-making techniques and the most advanced technologies. It represents the pinnacle of craftsmanship—a tool that not only performs exceptionally but also inspires creativity and passion in chefs around the globe.

-

Super Steel (Honyaki)

This knife is more than just a kitchen tool—it’s an extension of the chef’s hands, breathing life into every dish. As Japan’s knife culture evolves to new heights, Super Steel leads the way, embodying both tradition and innovation. It will continue to be beloved by chefs worldwide, elevating their craft and inspiring them for generations to come.

Advice from a Master Craftsman on Stainless Steel

-

-

"Stainless steel, once considered lacking in sharpness compared to traditional carbon steel, has come a long way due to advancements in modern technology. Today, high-quality stainless steel can offer sharpness and edge retention that rivals the finest traditional materials.

-

The key advantage of stainless steel is its rust resistance, which makes it an excellent choice for everyday use, especially for those in humid or salty environments. However, even with its durability, proper care and regular maintenance are essential to keep the blade performing at its best.

-

For those who appreciate both convenience and performance, stainless steel knives provide an outstanding balance, allowing you to enjoy the precision of a sharp blade while minimizing the maintenance required."

-

From the perspective of a traditional craftsman

-

The Science Behind Stainless Steel: Chromium’s Protective Bond with Oxygen

Stainless steel owes its renowned resistance to rust to the unique behavior of chromium. Before the steel can develop the dreaded red rust, the chromium in its composition reacts with oxygen in the air to form a thin, invisible layer of chromium oxide. This layer acts as a shield, preventing further corrosion and maintaining the steel’s integrity. It’s a brilliant interplay of elements—chromium and oxygen working together to preserve and protect. This natural barrier is what makes stainless steel such a trusted material in both everyday life and critical industries.

Understanding Stainless Steel: The Rust-Resistant Alloy

Stainless steel, enriched with elements like chromium, nickel, and vanadium, is celebrated for its corrosion resistance, a breakthrough in metallurgy achieved in 1913 by Harry Brearley. This advancement has led to widespread adoption in kitchen knives, particularly appreciated in settings like sushi restaurants for their ease of maintenance and hygiene. Recent innovations in high-carbon stainless steel have further enhanced these knives' sharpness, rivaling traditional carbon steel.

Japanese Knife Materials 4 Points

Knife material quality is defined by hardness, wear resistance, toughness, and corrosion resistance. These factors intricately determine sharpness, durability, and maintenance needs. Understanding their interplay unveils the essence of blade quality and its price range.

The Origin of Craftsmanship

-

The Harmony of Iron and Carbon: The Secret Behind Strong Blades

Iron, as a material, reveals its true potential when paired with carbon. The more carbon iron contains, the harder and sharper the blade becomes. This principle forms the foundation of Japan's centuries-old forging techniques.

-

However, as iron becomes harder, it also becomes more brittle. This delicate balance demands that we, as traditional artisans, approach the process with the utmost precision. We listen to the voice of the material, adjusting the composition and heat treatment with care, seeking the perfect equilibrium.

-

The story of iron and carbon is intricately woven into every blade. If you can feel the strength and finesse that resides in its edge, it brings us, as craftsmen, immense fulfillment.

Experience the sharpness trusted by 98% of Japan’s top chefs — handcrafted in Sakai City.

Through our exclusive partnership with Shiroyama Knife Workshop, we deliver exceptional Sakai knives worldwide. Each knife comes with free Honbazuke sharpening and a hand-crafted magnolia saya, with optional after-sales services for lasting confidence.

KIREAJI's Three Promises to You

-

1. Forged in the Legacy of Sakai

From Sakai City—Japan’s renowned birthplace of professional kitchen knives—each blade is crafted by master artisans with over six centuries of tradition. Perfectly balanced, enduringly sharp, and exquisitely finished, every cut carries the soul of true craftsmanship.

-

2. Thoughtful Care for Everyday Use

Every knife includes a hand-fitted magnolia saya for safe storage. Upon request, we offer a complimentary Honbazuke final hand sharpening—giving you a precise, ready-to-use edge from day one.

-

3. A Partnership for a Lifetime

A KIREAJI knife is more than a tool—it is a lifelong companion. With our bespoke paid aftercare services, we preserve its edge and beauty, ensuring it remains as precise and dependable as the day it first met your hand.