ZDP-189

-

Unmatched Hardness & Edge Retention

In a world of handcrafted blades and centuries-old traditions, ZDP-189 represents a new frontier — born not from the forge, but from advanced powder metallurgy.

With unmatched hardness, extraordinary edge retention, and the corrosion resistance of stainless steel, it redefines what a knife can be.

This is the steel for chefs who demand a blade that cuts flawlessly — and keeps cutting long after others have dulled. -

ZDP189 Japanese Knife Collection

-

ZDP189 Petty 210mm-Kido Finishing

Regular price $420.00 CADRegular priceUnit price / per$0.00 CADSale price $420.00 CAD -

ZDP189 Petty 210mm-Polished(both sides)

Regular price $527.00 CADRegular priceUnit price / per$0.00 CADSale price $527.00 CADSold out -

Sold out

Sold outZDP189 Gyuto (Kiritsuke) 240mm

Regular price $570.00 CADRegular priceUnit price / per$0.00 CADSale price $570.00 CADSold out -

ZDP189 Gyuto (Kiritsuke) 270mm

Regular price $610.00 CADRegular priceUnit price / per$0.00 CADSale price $610.00 CAD -

ZDP189 Gyuto 240mm-Mirror Polished(both sides)

Regular price $710.00 CADRegular priceUnit price / per$0.00 CADSale price $710.00 CAD -

ZDP189 Gyuto (Kiritsuke) 270mm -Mirror Polished(both sides)

Regular price $750.00 CADRegular priceUnit price / per$0.00 CADSale price $750.00 CAD -

ZDP189 Yanagiba (Sakimaru) 420mm-Mirror Polished(both sides)

Regular price $2,100.00 CADRegular priceUnit price / per$0.00 CADSale price $2,100.00 CADSold out

KIREAJI's Three Promises to You

-

1. Forged in the Legacy of Sakai

From Sakai City—Japan’s renowned birthplace of professional kitchen knives—each blade is crafted by master artisans with over six centuries of tradition. Perfectly balanced, enduringly sharp, and exquisitely finished, every cut carries the soul of true craftsmanship.

-

2. Thoughtful Care for Everyday Use

Every knife includes a hand-fitted magnolia saya for safe storage. Upon request, we offer a complimentary Honbazuke final hand sharpening—giving you a precise, ready-to-use edge from day one.

-

3. A Partnership for a Lifetime

A KIREAJI knife is more than a tool—it is a lifelong companion. With our bespoke paid aftercare services, we preserve its edge and beauty, ensuring it remains as precise and dependable as the day it first met your hand.

Why Many Product Photos Show Only the Blade

At KIREAJI, every knife is made to order in Sakai, Japan. Photos show the blade before the handle is attached, allowing artisans to perfect the balance and edge for your specific order. Your knife arrives fully finished — tailored just for you.

Global Delivery from Sakai

Across the world, discerning cooks seek authentic Japanese knives from Sakai — Japan’s legendary knife-making city with over 600 years of tradition.

At KIREAJI, we work alongside master artisans in Sakai to fulfill that desire, shipping genuine handcrafted knives directly from the workshop to kitchens worldwide.

ZDP189

-

Where Tradition Meets Innovation — The Future of Steel: ZDP189

“A knife is only as good as the steel it’s made from.”

Few in the culinary world would argue with that.

And when it comes to cutting-edge materials, ZDP189 stands at the forefront.Developed by Hitachi Metals using advanced powder metallurgy, ZDP189 is a premium stainless steel known for its extraordinary hardness and durability.

Though classified as a stainless steel, its performance far exceeds the conventional boundaries of that category. -

More Than Just Stainless — A Steel That Redefines Expectations

ZDP189’s greatest strength lies in its remarkable hardness of 66 to 68 HRC, paired with exceptional wear resistance.

This places it among the top-tier steels used in fine cutlery, delivering razor-sharp edges that hold for extended periods.

Once sharpened properly, it retains its cutting power for much longer than traditional steels.

Being stainless-based, it’s also much more rust-resistant than carbon steel, reducing the need for constant upkeep. -

A Blade That Answers the Demands of the Professional Kitchen

ZDP189 shines in high-volume, time-intensive culinary environments—where edge retention is not just helpful, but essential.

Even after hours of prep work, it maintains a clean, precise edge, helping chefs work faster and more efficiently.Yet because of its maintenance challenges, ZDP189 is a steel that demands respect, skill, and commitment.

In that sense, it is a steel that tests the chef as much as it serves them. -

ZDP189 — Steel for the Future

ZDP189 is more than a high-performance material—

it is a tool that expands the expressive capabilities of the chef, pushing the limits of what a knife can do.Yes, it is difficult to handle. But its rewards are immense.

ZDP189 is the steel that shapes the future—each blade a testament to what’s possible when craftsmanship meets cutting-edge technology.

Hitachi Metals' strongest powder steel, ZDP-189, boasts a hardness of 67 or higher, the highest of any known steel for cutting tools. It offers the ultimate combination of hardness, toughness, wear resistance, and corrosion resistance. However, due to its extreme hardness, ZDP-189 is difficult to sharpen with regular sharpening stones and is quite expensive.

Features of ZDP189

-

World-Class Hardness

ZDP189 is a high-hardness stainless steel developed by Hitachi Metals. Due to its extreme hardness, it maintains sharpness for extended periods.

-

Excellent Wear Resistance

Thanks to its high hardness, ZDP189 exhibits superior wear resistance compared to conventional stainless steels, reducing the need for frequent sharpening.

-

Challenging to Handle

ZDP189 is extremely hard, making it difficult to sharpen and unsuitable for beginners. Skilled technique is required for effective use.

Recommended Users for ZDP189

-

1. Professionals Who Demand Extreme Edge Retention

ZDP189 excels in maintaining its razor-sharp edge for extended periods, making it ideal for chefs in high-volume kitchens where constant re-sharpening is not an option. Perfect for long prep sessions without compromising precision.

-

2. Experienced Users Comfortable with Difficult Maintenance

Due to its exceptional hardness (66–68 HRC), ZDP189 is challenging to sharpen with standard whetstones. It is best suited for skilled sharpeners or those willing to invest in the proper tools and techniques.

-

3. Chefs and Collectors Seeking the Pinnacle of Stainless Performance

Combining stainless properties with elite hardness and wear resistance, ZDP189 is favored by both working professionals and collectors who value cutting-edge metallurgy in a blade that stands out in performance and prestige.

Knife Materials and Powder Steel — Where Tradition Meets High Technology

-

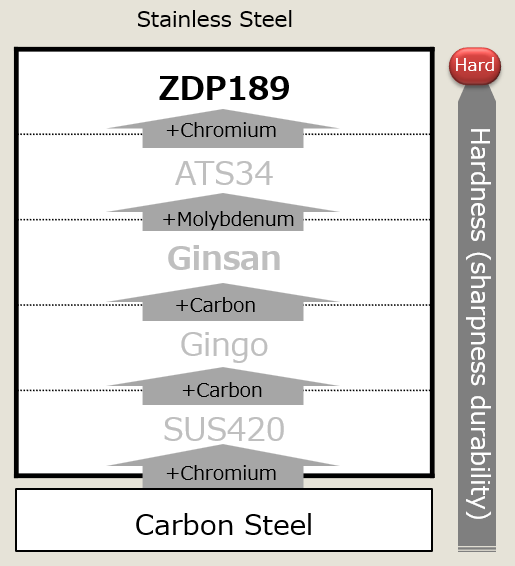

Japanese knives have long been crafted from carbon steel, alloy steel, and stainless steel. In recent years, a revolutionary process—powder metallurgy—has introduced a new generation of blade steels that push performance to new heights.

-

One standout example is ZDP189, developed by Proterial (formerly Hitachi Metals). Made by compressing powdered steel under heat and pressure, this method creates an ultra-dense, fine-grained structure with minimal impurities. The result is a stainless steel with extraordinary hardness (up to 67–68 HRC), exceptional wear resistance, and long-lasting sharpness.

-

-

Compared to traditional “melted steel,” powder steel offers more uniform grain and a finer cutting edge—ideal for precision slicing, even through tough ingredients. Chefs value it for the way it maintains razor-sharp performance during long prep sessions, reducing the need for frequent sharpening.

-

While its extreme hardness makes sharpening more challenging, those who master it are rewarded with a blade that combines cutting-edge technology with the soul of Japanese craftsmanship. Powder steel represents not just a new material, but a new frontier in knife making.

ZDP-189 Steel: Mastery Required for the Hardest Edge in Modern Cutlery

-

ZDP-189 is an ultra-hard powdered stainless steel engineered for extraordinary edge retention and extreme cutting precision.

With a hardness of HRC66–68, it ranks among the hardest steels ever used in culinary knives, maintaining a razor edge far longer than conventional stainless steels—even in relentless, high-volume environments.However, this performance comes at a cost: ZDP-189 is notoriously difficult to sharpen, demanding specialized stones, refined technique, and users with deep experience.

This steel is best suited for high-volume professionals, technical sharpeners, and performance-driven collectors who seek unmatched longevity and cutting performance, and who are equipped to maintain such a demanding material. -

FAQ about ZDP189

Q1. What is ZDP-189?

ZDP-189 is a high-performance powdered stainless steel originally developed by Hitachi Metals in Japan and now produced under Proterial, Ltd. With an exceptionally high carbon content (around 3%) and alloying elements such as chromium and molybdenum, it achieves some of the highest hardness levels in the world. This unique composition provides extraordinary edge retention, making it one of the most advanced steels ever used in kitchen knives.

Q2. What makes ZDP-189 knives special?

ZDP-189 knives are among the hardest stainless steel blades available, often exceeding 65–67 HRC in hardness. This extreme hardness means they maintain their sharp edge far longer than most other steels. Combined with excellent wear resistance and good corrosion resistance, ZDP-189 knives deliver extraordinary cutting performance for professional chefs and enthusiasts alike.

Q3. What are the advantages and disadvantages of ZDP-189?

The greatest advantage of ZDP-189 is its ability to deliver an extremely sharp edge and keep it for an exceptionally long time. Thanks to its high hardness and wear resistance, it offers cutting performance that few steels can match, while also maintaining good corrosion resistance as a stainless alloy. However, these strengths come with trade-offs. Because of its extreme hardness, ZDP-189 is difficult to resharpen without advanced skill, and its relatively low toughness makes it more prone to chipping if misused. In addition, its rarity and complexity of production make it more expensive than most other steels.

Q4. What precautions should I take when using ZDP-189 knives?

Because of its extreme hardness, ZDP-189 is more brittle than softer steels. Avoid cutting bones, frozen foods, or very hard items, as this can cause chipping. Use proper cutting techniques and always work on soft cutting boards such as wood or rubber. With careful use, the knife will maintain its incredible sharpness for an exceptionally long time.

Q5. How should ZDP-189 knives be maintained?

Proper maintenance ensures longevity: wash and dry the knife immediately after each use, sharpen it regularly with high-quality whetstones (advanced skill required), avoid hard surfaces, and store it in a dry place with a blade guard. Applying a thin coat of oil is recommended for long-term storage.

Q6. Who should consider purchasing a ZDP-189 knife?

ZDP-189 knives are best suited for experienced chefs and serious enthusiasts who appreciate high-performance steels and are willing to maintain them properly. They are not ideal for beginners, as sharpening and care require skill. If you value ultimate edge retention and cutting performance, and don’t mind investing in both price and effort, ZDP-189 is an excellent choice.

Japanese Knife Materials

The steel behind a Japanese knife defines its sharpness, durability, and care. From traditional carbon steels like White #2 and Blue #2 to modern innovations such as Ginsan and ZDP189, each material offers its own balance of performance and maintenance. This guide explores how these choices shape the knives we use today.

Is ZDP189 No Longer Available? — The Truth Behind the Legendary Steel

Once hailed as a “dream material,” ZDP189 is now disappearing from the market. This article uncovers the corporate strategy behind its decline and the possible end of this legendary steel—a must-read for collectors and craftsmen.

ZDP189 - The Pinnacle of Blade Steel

Originally developed by Hitachi Metals and now produced by Proterial, ZDP189 is a powder-metallurgy stainless steel renowned for extreme hardness, edge retention, and corrosion resistance. Though difficult to sharpen, it delivers unmatched performance and longevity, making it a top choice for high-end knives prized by professionals and enthusiasts worldwide.

The Soul of Craftsmanship

-

When the Human Hand Shapes True Precision

Sometimes, it is the touch of a human hand that creates the most precise and beautiful form. The true value of a tool lies not only in how it performs, but in the care and soul poured into its making.

-

Machines can reproduce uniformity, but they cannot breathe life into steel. Only through handcrafting—through the countless small decisions, adjustments, and instincts of an artisan—does a blade gain its character. Every mark of the hammer, every subtle movement of the whetstone, carries the spirit of the one who shaped it.

-

That is why I believe a handcrafted knife is never “just a tool.” It is a partner—alive with the warmth and dedication of its maker. And my hope is that every chef who holds it can feel that presence in their hands.

How Japanese Knives Are Made: The Sakai Tradition

VIDEO PROVIDED: JAPAN TRADITIONAL CRAFTS AOYAMA SQUARE (YOUTUBE)

-

Sakai Forged Blades — Six Centuries of Unrivaled Craftsmanship

Loved by chefs around the world and trusted by 98% of Japan’s top culinary professionals, Sakai knives are more than tools—they are the living legacy of over 600 years of master craftsmanship.

-

At KIREAJI, we work directly with the Shiroyama Knife Workshop in Sakai, Japan, ensuring every blade is hand-forged, finished to perfection, and shipped straight from the workshop to kitchens across the globe. No middlemen. No mass production. Only authentic, artisan-made knives, crafted to elevate your cooking for a lifetime.