What Are the Dimples on Japanese Knives? — How Urasuki Enhances Sharpness and Ease of Use

-

JUNE 10, 2023

-

Japanese knives are globally renowned for their exceptional sharpness and exquisite craftsmanship. These culinary tools are celebrated for their ability to deliver unparalleled precision and performance in the kitchen. A defining characteristic of many traditional Japanese knives, unlike their Western counterparts, is their single-edged (kataba) design. This asymmetry is not merely aesthetic but central to their specialized function and superior cutting capabilities.

-

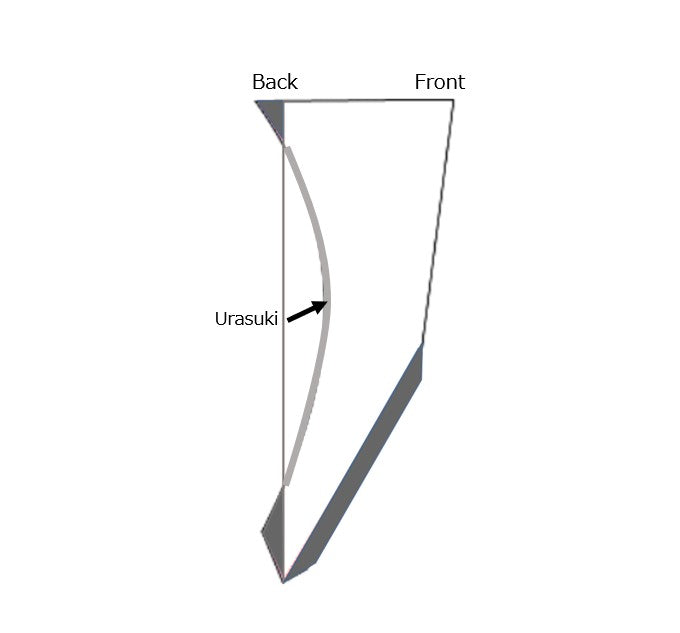

What truly sets single-edged Japanese knives apart is their unique blend of physical features: the subtle taper of the blade, the precise twist, and, crucially, the urasuki (back hollow-ground). These elements work in concert to minimize contact with ingredients, reduce friction, and deliver unmatched sharpness.

Urasuki refers to the distinctive indentation or concave shape found on the back (or ura) side of a single-edged Japanese knife. This unique design is a hallmark of traditional Japanese knives. While Urasuki is the most common term, it is also sometimes referred to as urabi or hizoko. This concave feature is a key differentiator, setting Japanese knives apart from Western ones, which typically have flat or double-beveled backs.

-

The primary functions and benefits of Urasuki are manifold. The most significant and frequently cited advantage is the reduction of friction and the facilitation of smoother cuts. The concave design dramatically minimizes the contact area between the blade and the food during cutting. This reduction in surface area translates directly into less resistance, allowing for incredibly smooth, precise cuts. This is particularly noticeable when working with moist or delicate ingredients, as it prevents the blade from sticking.

-

Furthermore, Urasuki enhances food release. By creating a subtle air pocket or space between the knife and the food, it ensures that slices separate cleanly from the blade. This is a critical advantage for tasks like slicing sashimi, where maintaining the integrity and freshness of the ingredient, and preventing tearing or sticking, is paramount.

-

Ease of sharpening is another vital role of Urasuki. The concave shape makes it easier to maintain a flat surface on the uraoshi (the flat rim around the concave) during sharpening, allowing the sharpening stone to make direct, consistent contact with the blade edge. This ensures that the edge can be sharpened precisely and consistently over time, preserving its geometry. The reduced surface area of the hard steel on the back also means less material needs to be removed during sharpening.

-

The combined effect of reduced friction and the ability to maintain a consistent, acute sharpening angle contributes significantly to the knife’s astonishing sharpness. This unique geometry allows for a thinner, sharper edge, even if the blade is thicker at the spine, making single-bevel knives extremely efficient. Some sources suggest that the Urasuki also contributes to the overall balance of the knife, making it feel lighter and easier to handle for intricate and precise cutting tasks.

-

Urasuki is more than a functional feature; it is a profound testament to the meticulous design, deep understanding of materials, and traditional craftsmanship inherent in Japanese knife making. It demonstrates how centuries-old traditional craftsmanship continues to adapt and meet contemporary culinary needs, embodying a blend of art and engineering. This feature enhances both cutting efficiency and usability, making Japanese knives with Urasuki highly valued tools for both professional chefs and culinary enthusiasts seeking to elevate their cooking experiences.

-

The unparalleled performance of Japanese knives is not attributable to any single "magic bullet" feature, but rather to a holistic, integrated design philosophy where multiple subtle elements are meticulously crafted to complement each other. For instance, the taper of the blade creates slight gaps between the knife and the ingredient, reducing friction; the twist aids cutting control by minimizing contact points; and the Urasuki specifically reduces friction and facilitates sharpening. This interconnectedness is a crucial distinction from simply listing individual benefits. This sophisticated design approach underscores the profound depth of traditional Japanese engineering, which intuitively understood complex physical interactions long before modern scientific frameworks were established. Understanding a Japanese knife means appreciating it as a finely tuned instrument where every curve and angle serves a purpose in harmony with the others.

-

Furthermore, Urasuki can be considered a "hidden" engineering marvel, as its importance is often underestimated or unnoticed by those unfamiliar with its intricacies. While the razor-sharp kireha (cutting edge) is the most immediately apparent feature of a single-bevel knife, the Urasuki on the back side is equally significant. Its concave nature might seem counter-intuitive for a cutting tool at first glance, yet its profound functional benefits—friction reduction, food release, and sharpening ease—are well-documented. This speaks to the intuitive mastery of fluid dynamics (preventing sticking) and material science (optimizing the sharpening of hard steel) possessed by traditional craftsmen. Urasuki thereby transcends a mere design element to become a symbol of ingenious, experience-driven innovation, reflecting a deep understanding of how to achieve maximum efficiency with minimal resistance.

The Artisan's Journey: Crafting the Urasuki

-

The creation of a traditional Japanese knife, including its Urasuki, is a complex, multi-stage process, often involving the specialized skills of numerous artisans. It is described as a "completed method" where the fundamental processes have remained largely unchanged over centuries, a testament to their enduring effectiveness. Japanese knives are typically made by forge welding a harder carbon steel (hagane) for the cutting edge to a softer, more flexible iron (jigane or gokunan-tetsu) for the body or support structure. This composite structure is fundamental, providing both exceptional sharpness and necessary resilience.

-

Below is a simplified overview of the Urasuki creation and refinement process:

-

Key Stages in Urasuki Creation and Refinement:

-

1. Forge Welding (Tanetsu):

The journey begins with the tanetsu process, where the softer jigane and the harder hagane (carbon steel) are meticulously joined. Both pieces are heated to extremely high temperatures, typically between 1000°C and 1200°C, until they glow red-hot. Borax and iron powder are applied as a flux, which helps to remove impurities and facilitates a strong, clean bond between the two steels. The heated steels are then hammered together repeatedly, forging them into a single, inseparable billet. While the Urasuki itself is not formed at this stage, this initial forge welding creates the foundational composite material. The precise combination and bonding of hard and soft steel are critical for the knife's overall strength, edge retention, and the ability to later form the delicate Urasuki without cracking or warping.

-

2. Forging (Tanzo) & Initial Shaping (Seikei):

Following forge welding, the composite billet undergoes the tanzo (forging) process. The steel is repeatedly heated (typically 800°C to 900°C) and hammered. This continuous heating and hammering not only shapes the knife roughly but also vitally tempers the steel, enhancing its hardness and flexibility, and refining its grain structure.

-

Creation of Urasuki (Seikei / Shaping): This is the pivotal stage where the Urasuki begins to manifest. During the Seikei (shape forming) process, the "mild concave on the backside of the knife which is vital to making a sharp single-edged knife" (Urasuki) is created. This is achieved by the artisan hammering the heated steel against an anvil. This is an incredibly delicate task, demanding immense precision and years of accumulated experience. Unlike double-edged knives, which are often shaped using mechanical presses and rollers, the flat surface and concave back of a single-edged knife are meticulously hammered by hand. The artisan uses a combination of mechanical spring hammers and smaller hand hammers to gradually thin and extend the blade while coaxing the subtle concave curve into existence. After the initial concave form is established, any excess material is carefully cut away, and the cut surfaces are ground to further refine the nascent Urasuki.

-

3. Heat Treatment (Yakiire / Yakimodoshi):

Once the knife has been roughly shaped, it undergoes crucial heat treatment to achieve its final, optimal balance of hardness and tenacity.

-

Yakiire (hardening): The blade is heated to a precise, high temperature (ranging from approximately 750°C to 1100°C, depending on the steel type) and then rapidly cooled by quenching it in water, oil, or air. This rapid cooling process transforms the steel's microstructure, making it extremely hard.

-

Yakimodoshi (tempering): Immediately following hardening, the blade is reheated to a lower temperature (typically around 150°C to 200°C) and allowed to cool naturally. This tempering process reduces the steel's brittleness, imparts flexibility, and increases its tenacity, making the blade resilient against chipping and breakage.

This step is fundamental to the knife's overall durability and performance. It ensures that the Urasuki, once formed, maintains its precise structural integrity and contributes to a resilient, long-lasting edge that can withstand the rigors of culinary use.

-

4. Grinding & Polishing (Kenma / Shiage):

Rough Sharpening (Aratogi): The process begins with initial grinding on coarse whetstones. This step removes any remaining distortions from forging, begins to thin the blade, and precisely shapes the kireha (cutting edge) and shinogi (ridge line). Critically, if the Urasuki's concave form is not perfectly adequate after forging, it is meticulously corrected and refined again using a hammer and chisel at this stage.

-

Flat Sharpening (Hiratogi): Further grinding ensures the blade's surfaces are perfectly flat, and the Urasuki's concave is precisely formed and smoothed. This is where the subtle, consistent curve of the Urasuki is perfected, ensuring its functional benefits.

-

Fine Sharpening (Hontogi): The blade is then progressively sharpened on increasingly finer grit stones to achieve its ultimate sharpness and polish. This includes meticulously refining the uraoshi (the narrow flat rim surrounding the Urasuki).

-

Finishing (Bokashi): The final step involves polishing the blade to a brilliant luster using buffing wheels. For traditional kasumi (misty) finish, a unique technique called bokashi is applied: natural whetstone powder is rubbed onto the jigane (soft steel) area, creating a hazy tarnish that beautifully accentuates the distinct boundary between the jigane and the shining hagane (hard steel) of the edge. This step highlights the visual beauty and precision of the blade, including the Urasuki's exquisite curve.

-

Throughout these stages, it is clear that creating a proper Urasuki is not a simple manufacturing step but a "delicate task that requires precision and care". It is a process that cannot be fully mechanized, relying instead on the "delicate hand of a skilled craftsman". The "Power of Dreams"—the tireless work and dedication to turn a vision into reality—is a tradition deeply ingrained and passed on by these master craftsmen. Each knife is imbued with "love and care". The quality of the Urasuki, including its depth and the straightness of its lines, can often indicate whether it was crafted by machine or by hand. Hand-crafted Urasuki often possesses a subtle "twist" or "hineri" that further contributes to its functional excellence and is a hallmark of true artisanal skill.

-

The creation of Urasuki is not merely a manufacturing process but an act of artisanal creation. The "how" is deeply intertwined with the human element—the artisan's intuition, experience, and touch. This implies a "living" quality to the craft, where the knife is not just a tool but an extension of the maker's spirit, accumulated wisdom, and dedication. For the user, this means owning a piece of functional art infused with human dedication and a legacy of mastery, rather than a mass-produced item. This perspective underscores the cultural value placed on profound skill, patience, and the intergenerational transmission of knowledge.

-

There exists a profound paradox in Urasuki's creation and maintenance, balancing simplicity with complexity. While the functional concept of Urasuki (reducing friction, aiding sharpening) is elegantly simple, its precise creation by the artisan and its long-term maintenance by the user are incredibly complex and demand exceptional skill. For instance, sharpening single-bevel knives is sometimes described as "pretty simple," requiring only to "follow the shape of the bevel that is already there." This suggests a deceptive simplicity. However, creating a proper Urasuki is a "delicate task that requires precision and care," and even the most skilled craftsperson is "not a machine." Furthermore, the existence of "bad Urasuki" and the difficulty in understanding its principles without proper knowledge are noted. It is also clarified that sharpening the Urasuki concave itself is a "specialized task typically done by professionals" and should not be attempted with standard sharpening stones at home. This highlights the high barrier to entry for true master craftsmen and explains why high-quality Japanese knives are so valued and often expensive. It also subtly suggests to users that while the knife is designed for ease of use, its underlying geometry is a testament to profound engineering and artisanal mastery, requiring respect and, at times, professional care.

Beyond Aesthetics: The Functional Brilliance of Urasuki

-

Urasuki's primary functional benefit is its significant contribution to the knife's sharpness by dramatically reducing friction during cutting. This design enables "smoother, more precise cuts with minimal resistance". This translates into a superior cutting experience for the user. The knife glides effortlessly through ingredients, rather than tearing or wedging, which is especially crucial for delicate tasks such as slicing sashimi or preparing paper-thin vegetables. The Urasuki design ensures only a minimal section of the knife touches the ingredient, delivering a smooth, seamless cutting experience that preserves the integrity of the food, a concept often referred to as "point contact".

-

The concave back creates a subtle air pocket or vacuum, effectively preventing food from adhering to the blade's surface. This is particularly effective with moist or sticky ingredients, ensuring clean separation and preventing drag. This feature is profoundly important in Japanese cuisine, where the visual aesthetics of the food and the precision of the cut are as highly valued as taste. The ability to slice delicate ingredients with minimal damage not only preserves their texture and flavor but also enhances the overall presentation, elevating the culinary experience.

-

While the Urasuki itself is the concave part, the knife features a narrow, flat rim around this concavity known as the Uraoshi. The Uraoshi is the critical part that makes contact with the sharpening stone on the back side of the blade. Its precise flatness allows for easier and more consistent sharpening of the back edge, ensuring the blade edge remains straight and its sharpness is sustained over time. The Urasuki's concave design makes the knife easier to sharpen by significantly reducing the surface area that needs to be ground on the hard steel back, meaning less material needs to be removed to achieve a burr. This unique design also plays a key role in maintaining a consistent sharpening angle as the knife wears down from regular use and sharpening, thereby preserving the blade's optimal geometry and performance.

-

By reducing friction during cutting, the Urasuki indirectly contributes to the longevity of the blade. Less resistance means less wear and tear on the cutting edge, helping to maintain its performance and sharpness even after long-term use. A well-executed Urasuki with sufficient depth also allows for more sharpening cycles over the knife's lifespan, extending its usability.

-

The precision, clean cuts, and aesthetic presentation enabled by Urasuki are deeply aligned with the core principles of Japanese cuisine. In this culinary tradition, the visual appeal, texture, and integrity of ingredients are just as important as their taste. The ability to slice delicate ingredients like sashimi or vegetables with minimal damage preserves their natural texture and vibrant flavors, directly enhancing the overall culinary experience and reflecting the chef's artistry.

-

Urasuki is more than a technical feature; it is an enabler of culinary artistry. Its design allows chefs to achieve a level of precision and delicacy that directly impacts the visual appeal, texture, and even flavor preservation of ingredients. This elevates the Urasuki from a practical design element to a sophisticated tool that facilitates the artistic expression inherent in traditional Japanese culinary traditions. It emphasizes how the tool itself is meticulously designed to support the highest standards of food preparation and presentation, making it an indispensable partner for the chef.

-

A sophisticated design strategy balances optimal cutting performance with practical user maintenance, seen in the symbiosis of the Uraoshi and Urasuki. Multiple sources clearly differentiate between the Urasuki (the concave part) and the Uraoshi (the flat rim surrounding it). They consistently clarify that the Uraoshi is the part that makes contact with the sharpening stone on the back side, while the Urasuki concave itself is generally not sharpened by the user and requires professional attention. There are also warnings that over-sharpening the Uraoshi can shorten the knife's life. This indicates a deliberate design choice. The Urasuki creates the profound functional benefits (friction reduction, food release), but the Uraoshi provides the practical, user-friendly interface for routine sharpening. This ensures that the knife remains sharp and effective over its lifespan without requiring everyday users to master the complex art of concave grinding. This design anticipates user needs and limits potential damage from improper sharpening, thereby extending the knife's longevity while preserving its core, unique functionality.

Parts of a Japanese Knife

We aim to introduce our customers to the parts and names of knives so that they can wield knives effectively, enjoy cooking more, and contribute to improving their culinary skills.

Japanese Knife Structure

We hope that by understanding the structure of knives, our customers will develop a greater appreciation for them and enjoy cooking even more. As their knowledge of knife structure deepens, they will gain a better understanding of how to choose and use their knives, making their daily cooking experience more fulfilling.

The Origin of Craftsmanship

-

The Power of Dreams, Crafted into Every Blade

"If you can dream it, you can achieve it." This is a belief that we, traditional craftsmen, have carried in our hearts for years. As I continue to create Japanese knives, I always keep these words close. Every day, as I strike the iron with sparks flying, breathing life into each knife, I feel an invisible force pushing me forward.

-

There's a saying, "No matter how fine the tool, it is the human who uses it." But I believe our craft is about shaping the dreams and desires of those who use our knives. When a chef picks up a knife, and with each cut, breathes life into a dish, that moment is the greatest joy for me as a maker.

-

To dream and to work tirelessly to turn that dream into reality—this is the tradition we must pass on. It is through this process that the tools we create, made with love and care, are transformed into beautiful dishes by the hands of those who use them. That’s why we continue to challenge ourselves, push boundaries, and create new value within our tradition.

Would you like to experience the sharpness of handcrafted knives from Sakai City, used by 98% of Japanese chefs?

Through our exclusive partnership with Shiroyama Knife Workshop, we bring you top-quality knives. In addition, we offer free Honbazuke sharpening, a protective Saya, and paid after-sales services to ensure long-term confidence.

KIREAJI's Three Promises to You

-

1. Exceptional Japanese Knives

Our knives, crafted by Sakai City's master artisans, combine traditional techniques with carefully selected materials, delivering unrivaled sharpness and durability.

-

2. For a Lifetime of Use

At KIREAJI, we see knives as lifelong companions. Each knife comes with a free saya, and we offer Honbazuke hand-sharpening by Shiroyama Knife Workshop in Sakai City.

-

3. Supporting the Joy of Continued Use

KIREAJI knives are made to grow with you. That’s why we provide trusted after-sales care (fee-based) .